Difference Between CNC Cutting Machine And Woodworking Engraving Machine

CNC cutting machine is a widely used and very intelligent woodworking machinery equipment. Do you know the characteristics of CNC cutting machine? How much do you know about this? Next, I will give you a detailed summary, I hope it can help you CNC cutting machine is one of the most widely used categories in intelligent woodworking machinery and equipment. It can be used not only in various industries such as wooden doors and furniture, but also in many hand-carvings, especially in the wood industry.

The huge cutting machine market has also attracted the development direction of many woodworking machinery manufacturers, and has entered the CNC cutting machine market. However, at present, there are not many equipments that can be regarded as real automatic CNC cutting machines, and many of them are transformed or extended from the structure of traditional woodworking machinery and equipment. So, what are the characteristics of a real cutting machine?

- The vacuum adsorption pump is reasonably configured, the power consumption is guaranteed, and the adsorption is good;

- The unique transmission system structure ensures precision and stable performance, and ensures the stability of the machine during long-term work and operation

At present, the speed of automatic feeding machine is relatively fast in China. The guide rail of the feeder driven by the servo motor adopts linear square guide rail, which has long service life and high precision; the control mode of the complete separation of the feeder driven by the servo motor is easy to operate, completely separated from the computer, and protects the computer from adverse environment. The x-axis dustproof structure of the cutting machine is driven by a servo motor, which avoids the easy entry of dust and damage to the guide rail slider when the machine moves at high speed.

According to the characteristics of CNC cutting machine, the above content has been introduced to you. It can be seen from this that the equipment configuration is relatively reasonable, the equipment adsorption is good, the accuracy of the equipment is guaranteed, and the processing speed is fast, which is very helpful for improving the processing speed of the equipment and solves the problem of tight supply in furniture factories. Therefore, a large number of furniture The factory began to purchase equipment.

CNC cutting machine and woodworking engraving machine belong to woodworking machinery processing equipment, which can be used for cutting and engraving. For example, the whole furniture customization, panel furniture production, office furniture production and children’s furniture production and processing, then what is the difference between them The difference between cutting machine and engraving machine.

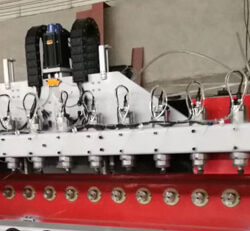

CNC woodworking engraving machine is mainly used for engraving and modeling, suitable for panel furniture cabinet door line engraving and wardrobe door hollow modeling CNC cutting machine is an upgraded and enhanced version of the engraving machine. All cutting machines can be done by CNC engravers. Due to different configurations, the processing accuracy and processing speed of the cutting machine are much higher than those of ordinary engraving machines. Functionally, the cabinet body and cabinet door can also be processed.

So, does CNC cutting machine have special advantages over woodworking engraving machine? Let’s analyze:

First, the structure of the engraving machine itself makes it impossible to cut for a long time. Generally speaking, the main configuration of the engraving machine is still the stepping motor. If it is processed for a long time, it is easy to lose the step due to the heating of the inner coil of the motor, which directly affects the engraving accuracy.

Second, the ordinary engraving machine does not have a positioning cylinder, resulting in large errors in the processing process, and the accuracy cannot meet the requirements. In addition, the front and rear of panel furniture often need to open holes and slots, and the lack of positioning cylinders will also lead to errors in the spacing between holes. 3. The running speed of CNC engraving machines is relatively slow, because ordinary engraving machines use stepper motors, while cutting machines are Servo motor is equipped with a reducer, so the power is more sufficient and the operation is more stable. In addition, ordinary engraving machines are basically spindles, which cannot realize automatic tool change. If you want to handle a complex process, you have to change tools manually, which is a huge waste of manpower and time. The CNC cutting machine can switch multiple cutter heads, easily realize the automatic tool change of three or four cutter heads and the wheel tool magazine, which can meet the needs of front and rear punching of the cabinet

So, what’s better than a CNC woodworking engraving machine? In conclusion, CNC engraving machines can do this, but engraving machines cannot. So if you just do some hollow engraving and relief cutting of door panels, you can choose woodworking engraving machine. If you make panel furniture, involving cabinet body and cabinet door, it is best to choose CNC cutting machine

Leave a Reply

You must be logged in to post a comment.