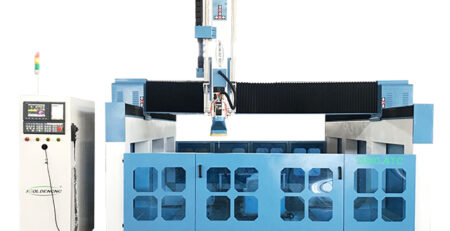

5 Axis CNC Bridge Saw Stone Cutting Machine

With the continuous progress of the times and the continuous innovation and breakthrough of science and technology, today’s stone industry is developing rapidly, which has driven the rapid development of other related industries, especially the development of stone machinery.

The 5 Axis cnc Bridge Saw is under computerized control, under the touch operating interface, and is equipped with wireless remote control, enabling the man-machine dialogue to be flexible and free. The main control components all use intermational famous brand components, cross frame oil diffuse type double V track, transverse knife adopts stepless frequency conversion speed regulation, longitudinal spliter adopts linear guide rail and high precision magnetic ruler count, to ensure the bridge cutting machine work stable and stable precision.

The Way to Reduce Noise of 5 Axis cnc Bridge Saw

Firstly, we should choose the right way to cut stone. For example, each of blade feeding depth should be appropriate according to stone hardness. If the stone is soft, the blade can feed deeper. If the stone is hard, the blade can feed less deep. If the blade feed too much, the cutting noise will be very big.

Secondly, the 5 Axis cnc Bridge Saw can be designed into a specific structure which will make less noise. And find a way to restrain the vibration of blade is especially useful for noise control.

Thirdly, we can give protection to 5 Axis cnc Bridge Saw operator passively. For example, insert cotton in their ears, wear earplug or helmet. All these are effective ways to protect operator from the hazard of noise. Other ways including stop the noise by a wall, install a device to adsorb the noise, etc. Some marble cutting machine manufacturer designs the blade cover to have the function of stopping noise, so as to reduce the harm of noise to the operator.

5 Axis cnc Bridge Saw Features

1.Blade can tilt 0-90° ,full automatic vertical and horizontal switch cutting repeatedly by one-button, 0°-90°-180°-270° automatic positioning chamfering cutting.

2.Worktable can rotate 0-360° and tilt 0-85°, easy for cutting direction changing and slab loading.

3. Crossbeam and carling adopt Taiwan’s Hiwin linear guide to move, which ensure high precision of cutting and long life.

4. Using Siemens PLC control system with and touch-sensitive screen offer friendly and inteligent control.

5. Electric components adopts Siemens or Schneider brand

6. Laser checking and calibration instrument to aid in lining up the cut.

Leave a Reply

You must be logged in to post a comment.