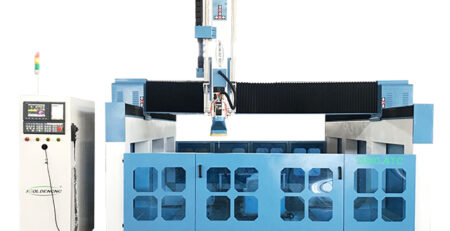

New Kitchen Cabinet Door Making Cnc Router Machine

The kitchen cabinet door making cnc router machine is all steel construction providing the rigid foundation required for ultra-smooth routing results.

CNC Nesting Machine with Drilling

While for mass production factories, CNC machines are the best choice. The high automation degree of CNC machinery greatly improves the cabinet door making efficiency. And the finished cabinet doors have high precision and good repeatability, which ensures the consistency of the products. For cabinet door making factories, I recommend a production solution to solve the problem of how to make cabinet doors. This solution is especially designed for making PVC filmed cabinet doors. This solution mainly consists of such cnc machines for cabinet making as 1325 linear ATC machining center, edge banding machine, side drilling machine, vacuum press machine, precision saw, hinge drill and metal strip cutting machine. Flexible combinations of these CNC machines can achieve multiple processes, and create an automatic production line meeting customer requirements. This production line is quite suitable for making cabinets and cabinet doors.

Kitchen Cabinet Door Making Cnc Router Machine Features:

1. The whole bed is welded by seamless steel structure, tempering and aging treatment, with strong rigidity and no deformation.

2. Taiwan linear square guide, double row of four row ball slide block, heavy load bearing, smooth operation, high precision, long life, double screw with high precision and precision cutting.

3. Original air cooling spindle 6kW and 4.5kw and the cutting intensity is large.

4. With independent cabinet, separate keyboard operation, split type keyboard operation,easy to learn, and flexibly grasp the use of equipment, more independent.

5. With vacuum equipment and the six zoning vacuum adsorption table is specially designed for the soft material, such as density plate. It can also place different sizes of plates, keep the flatness of the plate surface, make the engraved effect diagram consistent, and improve the loading and unloading time. The vacuum system can be processed in the processing process. Remove wood chips and froth, keep the worktable clean and maintain the equipment indirectly.

This kitchen cabinet door making cnc router machine closet door furniture production has multi-functions of carving, engraving, milling, slotting, grooving, cutting, chamfer edge.

Kitchen cabinet door making cnc router machine s mainly used in the furniture making industry, especially cabinet closet and door industries.

The Frame or frameless cabinet construction

Entertainment units

Kitchen cabinets, islands and peninsulas

Closets: Walk-ins, Reach-ins, Entries, Pantries

Angled and radius cabinets and countertops

Vanities

Bookcases

Home office workstations

Fine custom cabinetry… and much more

Leave a Reply

You must be logged in to post a comment.