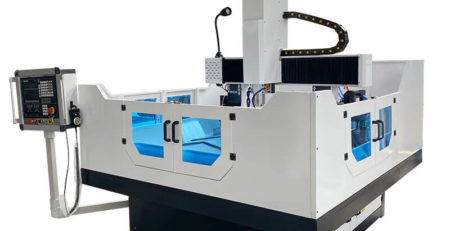

Why do We choose Automatic Cabinet Making CNC Machine?

Automatic Cabinet Making CNC Machine using Japan Yaskawa servo 850W motor and drive reducer, automatic lubrication system. When it works, it becomes easy to operate. Can also be automatic feeding, automatic blanking.

Kitchen Cabinet Door Making Machine Applications:

The most advanced, multi-function ATC Nesting CNC machine with drilling bank, perfect for professional scaled furniture manufacturers, designed by igoldencnc for changing tools automatically while working, combined with a competitive set of configurations.

Hot Applications Include:

>Production and processing of various types of furniture: cabinets, wardrobes, office furniture, computer tables, children’s furniture, panel furniture, cutting and cutting, slotting and perforating, decoration hollow frames, soft bag background wall production, etc.;

>Wooden door and furniture decoration industry: solid wood and composite door, cabinet door, large-area plate carving, solid wood, panel furniture carving, solid wood art mural carving, etc .;

>Wood products processing: clocks, sporting goods and equipment;

>Musical instrument industry: three-dimensional curved surface and shape cutting of sculpture musical instruments;

Crafts industry: photo frames, jewellery boxes.

Cabinet door Automatic Cabinet Making CNC Machine Parameters:

XYZ working area:2100*2800*300mm

Spindle:Italy HSD brand Air cooling 9kw ATC spindle, round disk tool magazine 12 pieces and HQD 9 holes vertical drilling unite (4+5)

Guide rail:Italy PEK square guide rail

Table:Vacuum adsorption table / Positioning cylinder / Auxiliary feeding

Vacuum pump:Air cooling 7.5kw

Motor:Japan yaskawa servo 850W motor and driver and reducer

Inverter:Taiwan Delta 11kw

Control system:Syntec control system 6MB with independent control cabinet

Lubrication system:Automatic types

Leave a Reply

You must be logged in to post a comment.