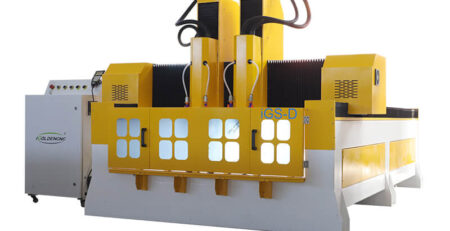

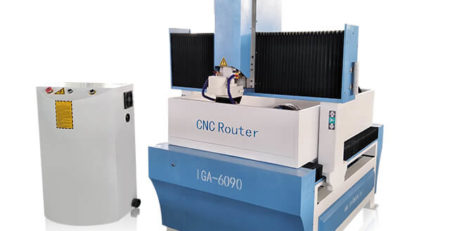

7 Technical Characteristics Of CNC Router Wood

This 4 axis cnc router wood is a cost-effective intelligent CNC Carving Machinery, which integrates automatic positioning, optimized cutting, punching, slotting and engraving, so as to maximize the use efficiency of labor.

1. Intuitively display the processing process and observe the processing effect. The rationality of the processing effect can be inspected in advance, which can reduce the trial cutting process and reduce the bottom processing cost.

2. The processing plan can be evaluated to assist you in choosing a reasonable processing technology.

2. Breakpoint memory function

When your equipment is suddenly powered off (or the knife is broken, or half of the material processed by the material is not finished, or some parts still need further processing), you can use this function to continue the engraving work.

3. Optimized the arc command

Engraving a circle is as fast as engraving a straight line, and the cut surface is very smooth. After using the arc command, the engraving curve is faster and smoother, the relief effect is better, and there is no pause in the engraving process.

4. Compatible with all kinds of excellent carving software in the world

Connect the world’s best engraving software, such as MASTERCAM\ARTCAM, etc. It can also be compatible with domestic engraving software, such as Jingdiao JDP, Wentai, etc.

5. You can directly edit the raw G code

When the G code made by the user needs further modification, it can be directly read (opened in the notepad format of WINDWS), which facilitates your operation of the file.

6. cnc router wood can be programmed by itself

You can directly edit some concise programs to test the performance of the equipment, and you can also call in advanced users for special needs

7. processing timing

The program greatly facilitates your choice of purchasing a machine. You can compare a piece of the same processed part and then choose the product you are satisfied with. If you need to mass produce the product, you can budget your processing time and help you choose The most efficient processing mode.

Woodworking engraving machine vacuum adsorption table

The vacuum adsorption table is to put a density board directly on the table after plugging the sealing strip, and the workpiece can be sucked by turning on the vacuum pump. This table saves fixed time and is especially suitable for large-scale processing in the wood door industry.

Sometimes it is necessary to put a thin osong board first, which is formed by wood fiber and glue under high pressure. There are pipes or gaps between the wood fiber itself and the wood fiber. Therefore, the osong board still has certain Breathable.

The Aosong board is placed on the vacuum adsorption table of the cnc router wood to prevent the milling cutter from hurting the work table. The pressure of the workpiece at the position close to the density board is much less than the atmospheric pressure on the other side, forming a so-called negative pressure. Just like two pieces of glass combined together, the principle that it is not easy to separate is the same. Once the seal is not tight, negative pressure cannot be generated, that is, the pressure on both sides of the workpiece plate is the same, it is easy to move.

Here, the cnc router wood manufacturer tells you a little trick to use the control system to avoid the engraving error of the woodworking engraving machine.

Simulation function of CNC woodworking engraving machine control system

1. Using simulation, we can examine the program to be processed. If the program input is wrong, we can adjust it in time to avoid processing errors in the woodworking engraving machine;

2. Using simulation, you can preview the processing effect in advance. If the effect is not very good, we can re-select the appropriate tool to calculate the path;

3. Using simulation, we can calculate the time required for actual processing in advance, so as to arrange our time reasonably;

4. Using the simulation, it is possible to check the lift distance of the tools and the order of the tools. The tool lift is too high or too low, and the engraving sequence is disordered, which can be adjusted through this link.

For users who are new to woodworking engraving machines, the importance of simulation is particularly important. The operation itself may be a little unfamiliar. If the simulation preview is not performed again, once a problem occurs in a certain link, it may cause material waste or tool breakage. Simulation is equivalent to an actual process. Use simulation software to demonstrate while learning, making it easier to master.

In order to avoid damage caused by improper operation of the woodworking engraving machine, and in order not to waste plates and save manpower, etc., everyone must be cautious when operating, that is, employees who are skilled in woodworking engraving, it is recommended to use the simulation function of the micro-macro system before engraving , check the engraving path is correct, etc.

Leave a Reply

You must be logged in to post a comment.