CNC engraving machine, what kind of engraving machine

Type 1: CNC woodworking engraving machine

CNC wood engraving machine is an entry-level CNC wood engraving machine for the woodworking industry. Its advantages are low cost, convenient operation and maintenance. The CNC woodworking engraving machine can move on three different axes at the same time (such as X, Y, Z axis).

The layout is designed by CNC software, and the engraving process of X, Y, and Z axes generated by the CNC woodworking engraving machine is controlled by the controller, which can process the materials fixed on the worktable and meet the different requirements of customers for the workpiece. This CNC woodworking engraving machine mainly processes various panels. If you only work on some wooden boards, this CNC wood engraving machine is undoubtedly the ideal choice for you. Standard three-axis CNC engraving machines on the market also include multi-head CNC machine tools, multi-process engraving machines, etc.

Type 2: ATC CNC engraving machine

ATC CNC engraving machine is equipped with automatic tool changer. This type of CNC wood engraving machine can meet the needs of equipment replacement during the entire processing process without personal participation.

Compared with traditional hand tools, this CNC woodworking engraving machine can be equipped with various tools. It is adjusted by a computer system program and can automatically change the required tool during the machining process. Therefore, various processing requirements such as cutting, hollowing, grooving, punching, grooving can be completed at the same time. This not only saves time, but also greatly improves processing quality and production efficiency. Therefore, this type of engraving machine is the first choice for large enterprises.

Compared with traditional hand tools, this CNC woodworking engraving machine can be equipped with various tools. It is adjusted by a computer system program and can automatically change the required tool during the machining process. Therefore, various processing requirements such as cutting, hollowing, grooving, punching, grooving can be completed at the same time. This not only saves time, but also greatly improves processing quality and production efficiency. Therefore, this type of engraving machine is the first choice for large enterprises.

Type 3: Four-axis CNC engraving machine

Four-axis CNC woodworking engraving machine refers to a CNC engraving machine that can process X, Y, Z and A axis trajectories. The main shaft of this four-axis CNC engraving machine can swing left and right. As a result, the spindle can be brought close to the workpiece and efficiently machined from many different angles.

Therefore, it can realize not only plane engraving, but also three-dimensional engraving and some irregular workpieces. In addition, this CNC wood engraving machine can reduce spindle vibration by controlling the machining angle, prolong the life of the machine tool, and use the geometry of the tool to improve machining stability and accuracy. Therefore, the four-axis CNC woodworking engraving machine can realize three-dimensional working parts such as keel, Guanyin statue, Buddha statue, Roman column, etc. If you have a variety of processing requirements, such as three-dimensional workpieces, complex workpiece parts, and irregular-shaped workpiece parts, the four-axis CNC engraving machine can meet your diverse processing requirements.

Type 4: Rotary axis CNC engraving machine

Rotary axis CNC engraving machine, also known as four-axis CNC wood engraving machine, is equipped with a rotating device. Mainly machining cubic or cylindrical workpieces.

During the processing of the rotary axis CNC woodworking engraving machine, there is no need to repeatedly rotate the workpiece, which saves time. Compared with the ordinary CNC woodworking engraving machine, the rotary engraving machine reduces the manual workload and improves the production efficiency. Furthermore, since the spindle tool can be machined in this layer, a higher machining quality can be ensured.

The fifth category: CNC stone engraving machine

The stone carving machine is designed for all kinds of stone processing. Its processing path is the same as that of ordinary engraving machine. Machining functions include embossing, lettering, hollowing, cutting, seamless sewing, surface treatment, table milling.

The engraving machine is mainly suitable for processing various hard materials, such as stone, metal, jade, crystal, wood, artificial materials, synthetic materials, etc. And it is widely used in inscriptions, garden projects, large-scale sculptures, craft engravings, home decoration, movies and other industries.

Type 6: Five-axis CNC engraving machine

Five-axis CNC engraving machine is a high-end CNC machine tool, which refers to a CNC engraving machine with at least five coordinate axes (three linear coordinates and two rotary coordinates) on the machine tool.

The five-axis CNC engraving machine has high technical content and high processing precision, and is especially suitable for processing complex curved workpieces. At present, five-axis CNC machine tools are the only means to solve the problems of impellers, blades, marine propellers, heavy generator rotors, steam turbine rotors, and large diesel engine crankshafts. In addition, CNC equipment plays an important role in aerospace, military, scientific research, precision equipment, high-precision medical equipment and other industries.

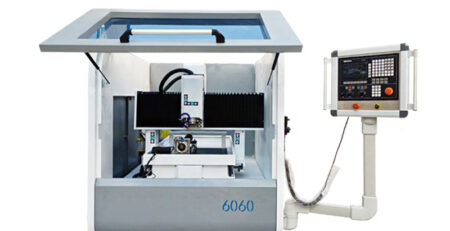

The seventh category: mini CNC engraving machine

Mini CNC engraving machine, also known as small engraving machine, home CNC engraving machine, hobby CNC engraving machine. Small CNC engraving machines are relatively small compared to other standard CNC machines. Therefore, it is suitable for processing small engraved surfaces, such as badges, sand table models and surface treatment of handicrafts.

The small size has particularly distinct advantages in terms of packaging and shipping. The packaging is convenient, and it also saves a certain cost for the user. If the motor power of the micro engraving machine is upgraded, this type of engraving machine can also be used to make crystal characters, various types of advertising signs and irregular sheet cutting. The small engraving machine has the advantages of compact structure, small area, convenient mobile use and so on. It will be popular with woodworking enthusiasts and the advertising industry.

Type 8: EPS/foam CNC engraving machine

EPS CNC foam cutting machine is also called CNC foam cutting machine. Compared with the heavy metal cutting machine, the foam CNC machine is a light CNC machine. This type of foam CNC engraving machine has a larger machining size and machining stroke than standard CNC machines.

Especially in the mold industry, such as automobile foam molds, plaster molds, paraffin molds, large ship wood molds, aviation wood molds, propellers and wooden train molds, this foam CNC engraving machine is very popular.

Leave a Reply

You must be logged in to post a comment.