Cost-effective – Handheld Laser Welding Machine

Handheld laser welding machine adopts the latest generation of fiber laser, which has the advantages of simple operation, beautiful welding seam, fast welding speed and no consumables. It can perfectly replace traditional argon arc when welding thin stainless steel plates, iron plates, aluminum plates and other metal materials. Welding and electric welding process. Hand-held laser welding machine can be widely used in complex and irregular welding processes in cabinet kitchen and bathroom, stair elevator, shelf, oven, stainless steel door and window guardrail, distribution box, stainless steel home and other industries.

Advantages of handheld laser welding machine

Laser: high stability, less maintenance, more energy saving

The laser uses Raycus continuous fiber laser, which has the advantages of high stability, less maintenance and more power saving compared with other commercial pulsed lasers, which effectively reduces the cost of equipment use and optimizes the use experience.

Fiber Optic Cables: Extra Long, More Flexible

The transmission fiber adopts the special fiber for fiber laser, which can be welded over a long distance, which is convenient for on-site operation.

Water cooler: internal and external circulation, high efficiency and stability

Water cooler: internal and external circulation, high efficiency and stability

The water cooling system is composed of an inner circulation system and an outer circulation system. The inner circulation system is self-contained by the laser, and the outer circulation system adopts a laser-specific water cooling unit to ensure the long-term stable operation of the laser.

Operation panel: easy to use

Chinese operation display, no need for complex training, easy to master the operation mode, and the working status is clear at a glance.

Some other features and advantages of hand-held laser welding machine

- The welding speed is fast, 2-10 times faster than traditional welding, and one machine can save at least 2 welders a year.

- Less consumables for laser welding and long service life.

- The operation is simple, you can work without an employment certificate, and you can weld beautiful products without a master.

- The welding seam is smooth and beautiful, reducing the subsequent grinding process, saving time and cost.

- The welding workpiece has no deformation, no welding scar, and the welding is firm.

- Safer and more environmentally friendly.

- The self-developed welding head makes up for the disadvantage of small laser welding spot, expands the tolerance range of processed parts and weld width, and obtains better weld formation.

Laser welding machine, also known as laser welding machine in the industry, is mainly used for metal material welding, and non-contact welding can meet environmental protection requirements. Mainly used for welding of large machinery and equipment and precision parts, it can realize spot welding, butt welding, stitch welding, sealing welding, etc. After welding, the width is small, the depth ratio is high, the heat effect is small, the deformation is not easy, the welding speed is fast, the weld seam is flat and beautiful. The laser welding quality is high, there is no air hole, the focus point can be precisely controlled, the positioning accuracy is high, and automatic welding can be realized.

It is widely used in welding of various metals and alloys such as aluminum, steel, iron, titanium, gold, silver and so on.

Laser welding machine features

Long service life, simple operation, beautiful welding (no deformation, no welding scars), fast welding speed, no consumables, more safety and environmental protection, and can be operated without an employment certificate.

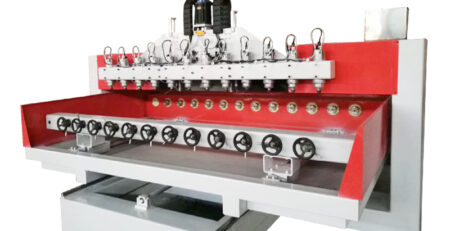

Fiber Laser Welding Machine

Continuous fiber laser welding machine is a professional laser welding equipment used in traditional hardware, new energy and other industries. It has the advantages of high power peak value, good beam quality, small spot size and flexible installation. The laser beam can realize different spot shapes, can process special-shaped spots at the same time, meet various high-demand welding effects such as hybrid welding, and realize precise and efficient welding.

What are the characteristics of precision welding of laser welding machine

When using a traditional welding machine to weld workpieces, because manual measurement of welding data and manual feeding of materials are used, the accuracy of the welded workpieces often fails to meet the requirements, and subsequent complicated processes are required for precision machining. Reduced work efficiency and increased production costs. The laser welding machine uses the numerical control system to weld the workpiece, which can greatly ensure the welding accuracy and avoid the complicated process of secondary processing. Let’s talk about the characteristics of precision welding of laser welding machine:

Feature 1: The laser welding machine adopts the numerical control system to control the various functional components of the welding machine to weld the workpiece. It is only necessary to measure the parameters to be welded before welding, and input the correct parameters on the numerical control panel, and the laser welding machine can weld the workpiece. After welding, the precision of the workpiece produced by the welding machine meets the requirements, and the appearance is flat and beautiful.

Feature 2: After the workpiece is welded by ordinary welding methods. Generally, the accuracy will not meet the requirements, and the appearance will be uneven and rough, and there will be burrs. The laser welding machine is the finishing process of these workpieces, which can precisely weld the workpieces. Therefore, precision welding is the most important welding method in industrial production and processing.

Feature 3: When using the precision welding method of the laser welding machine to weld the workpiece, the suitable welding head and suitable welding method can be selected according to the actual welding situation and the properties of the material. There are many methods that can be used in the welding process. For example, close seam welding is divided into several fine means.

Feature 4: The precision welding of the laser welding machine is not limited to the properties of the material and the requirements of environmental factors. It can weld any shape and any part of the welding material. In addition, the energy consumption in the welding process is small, which greatly improves the production efficiency and saves the production cost.

Leave a Reply

You must be logged in to post a comment.