Difference Between Woodworking Engraving Machine And Laser Engraving Machine

With the improvement of living standards and the vigorous development of the manufacturing industry, people have put forward requirements for the appearance and variety of wood panel decorations. Wood panel products are designed manually, and the materials are processed and carved to achieve beautiful effects. Today we will introduce the wood laser engraving machine.

Most of the traditional wood products are manually engraved, which is time-consuming and labor-intensive, with low work efficiency, and the engraving accuracy is not high. It is necessary to constantly flip the angle to engrave, and it is easy to cause fatigue after a long time.

The existing laser engraving machine can not only save most of the manpower, but also the finished product engraved is beautiful and fashionable, which is loved by the majority of engraving manufacturers.

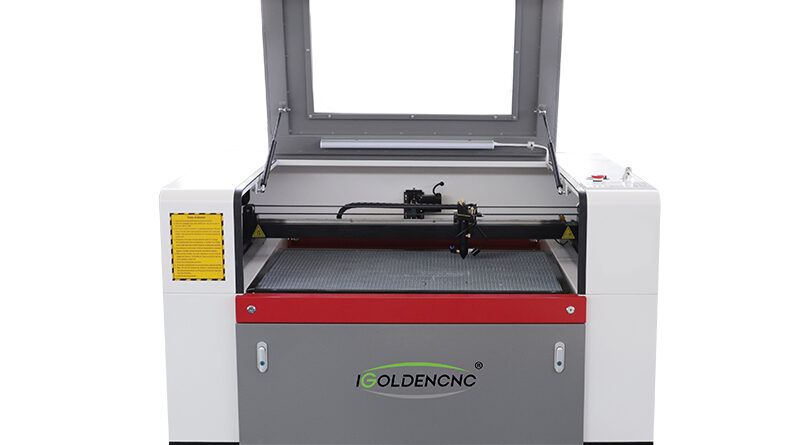

However, most of the laser engraving machines on the market at present are too large in size and occupy a relatively large area. Especially when engraving materials such as wood boards, the materials need to be fixed, but the existing laser engraving machines The clamping effect is poor, resulting in movement or shaking when the material is engraved, which affects the engraving effect. Moreover, during the cutting and engraving process, wood dust will be generated, which will affect the production workshop environment.

In order to solve the problems existing in wood panel engraving, wood panel laser engraving machine came into being.

The equipment is small in size, saves production space, and reduces the cost of land occupation; it adopts an environmentally friendly smoke exhaust system to efficiently remove dust and reduce environmental pollution.

Independent research and development of high-performance control motherboard, user-friendly software operation, can support DXF, AI, PLT, DST, DSB and other graphic formats.

High-precision linear guides, driven by stepping motors, and fast-moving with a lightweight laser head; the effective working width is 400*300mm, the overall volume is small, and the engraving precision is high.

It is mainly suitable for personalized fine processing of seals, business cards, gifts, greeting cards, etc., and can be used for non-metallic materials such as wood products, paper, plastic, acrylic, rubber, jade, etc.

Comparison of the advantages and disadvantages of wood board laser engraving machine and woodworking engraving machine

The main difference between woodworking engraving machine and laser engraving machine lies in the way of engraving. Laser engraving machine uses laser light source as engraving energy to engrave; while woodworking engraving machine uses metal knives for engraving. Specifications are very high.

Woodworking engraving machine and laser engraving machine

The main difference between the two is

- In terms of engraving precision, the laser engraving machine has higher precision than the woodworking engraving machine, because the diameter of the light source of the laser engraving machine is very small; and the woodworking engraving machine itself has a certain knife width, so in terms of accuracy, in addition to the machine The quality itself also includes the precision requirements of the tool.

- In the choice of engraving materials, it is difficult for laser engraving machines to achieve deep engraving on metal materials, and it may only be coating engraving on the metal surface; while woodworking engraving machines can achieve a certain depth of engraving, even cut.

- The laser engraving machine is a non-contact processing object, and there is no need to fix the workpiece for plane engraving; while the woodworking engraving machine requires the workpiece to be fixed because it is a contact engraving.

- The laser tube of the laser engraving machine has a certain life time limit, while the mechanical woodworking engraving machine does not have a time limit, but the tool wear will also occur. In the case of serious wear, it is necessary to replace the tool.

- In the plastic engraving process, the laser engraving machine may produce toxic gas, and a specific air purification system is required to discharge the waste gas into the air; while the woodworking engraving machine will not pollute the air.

- The laser engraving machine is very good at engraving photos. It can directly engrave photos in JPG format, but the woodworking engraving machine cannot do this.

Leave a Reply

You must be logged in to post a comment.