Handheld Continuous Laser Welding Machine

The laser handheld continuous laser welding machine is widely used in many industries such as kitchens, household appliances, advertising, molds, stainless steel doors and windows, handicrafts, household goods, furniture, auto parts, etc.

Technical features of handheld laser welding machine:

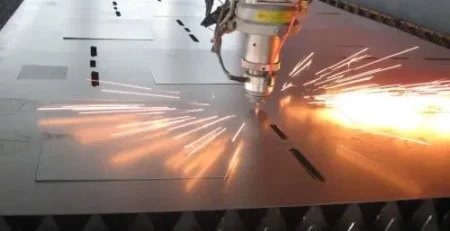

- The hand-held laser welding machine uses a hand-held welding gun to replace the previously fixed optical path, subverting the previous working mode of the laser welding machine.

- The precise positioning of the red light is easy to observe, the operation is simple, and the welding can be done by hand. There is no need to spend a large amount of cost to ask the welding master.

- Compared with the deployment of fully automatic equipment, the handheld laser welding machine has a lower production compliance rate. However, for production workshops engaged in small-scale processing or non-large-scale welding, manual laser welding is the best choice. There is no need to set up equipment to deploy the welding table, which takes up little space. The important point is the diversification of welding products in small workshops and the flexible product shape. Manual laser welding can fully meet the needs of this kind of production, with better compliance.

The optical fiber hand-held laser welding machine replaces the previous fixed optical path with a hand-held welding gun. It is flexible and convenient for welding by hand, and the welding distance is longer.

Overcome the limitations of the workbench space, and can be used when the workpiece size is not uniform and cannot be automatically welded.

Mainly for large workpieces, fixed positions such as inner right angles, outer right angles, flat welds, small heat-affected areas during welding, small deformation, large welding depth, and strong welding. It is a new and flexible welding process for long-distance welding of large workpieces.

The optical fiber hand-held laser welding machine uses a hand-held welding gun to replace the previous fixed light path. It is flexible and convenient for welding by hand, and the welding distance is longer to overcome the limitations of the worktable space. It can be used when the workpiece size is not uniform and cannot be automatically welded.

Mainly for large workpieces, fixed positions such as inner right angles, outer right angles, flat welds, small heat-affected areas during welding, small deformation, large welding depth, and strong welding. It is a new and flexible welding process for long-distance welding of large workpieces.

Product application of handheld laser welding machine:

Used in welding of shelves, kitchens and bathrooms, household kitchen utensils, stainless steel doors and windows, ovens, distribution boxes, aluminum alloy doors and windows, stainless steel furniture, stainless steel display racks, etc.

- Small and beautiful, easy to move push-pull handle, universal casters, can move around, easy to weld objects that are not easy to move;

- Flexible, light and arbitrary welding of handheld laser heads, light and flexible, can achieve long-term welding of workpiece parts and not easy to fatigue;

- Good welding quality, less consumables and simple operation. Compared with traditional hand-held laser welding, it has obvious advantages and low equipment maintenance cost, which can meet the welding needs of different products;

- The core parts of dual-temperature dual-control water-cooling have a stable performance and a long life, which can protect the normal operation of the machine and prolong the use time.

Leave a Reply

You must be logged in to post a comment.