Hot Sale Tire mold laser cleaning machine

There are many rubber products currently produced, and the molds for producing these rubber products are easily contaminated. In order to maintain normal accuracy, surface dirt must be removed. Various conventional cleaning methods (dry ice, sandblasting, chemical agents) cannot meet the production needs. It is under this demand that laser cleaning technology is applied to the cleaning of rubber product molds. Laser cleaning is a new type of industrial cleaning technology. It has the advantages of green environmental protection, high cleaning power and low labor intensity. It is a cleaning technology with great development potential and practical value. The following introduces the cleaning application of laser cleaning machine on rubber molds.

The cause of the surface contamination of the rubber product mold was determined, and the main adsorption force between the rubber particles on the mold surface and the substrate was determined to be the van der Waals force. The practical application of laser cleaning rubber product mold technology is studied. After using the laser cleaning technology to clean the sealed mold, it is not difficult to see the advantages of the laser cleaning technology. Laser cleaning will be the mainstream of mold cleaning in the future, and laser cleaning technology will definitely play an important role in the mold industry.

The cause of the surface contamination of the rubber product mold was determined, and the main adsorption force between the rubber particles on the mold surface and the substrate was determined to be the van der Waals force. The practical application of laser cleaning rubber product mold technology is studied. After using the laser cleaning technology to clean the sealed mold, it is not difficult to see the advantages of the laser cleaning technology. Laser cleaning will be the mainstream of mold cleaning in the future, and laser cleaning technology will definitely play an important role in the mold industry.

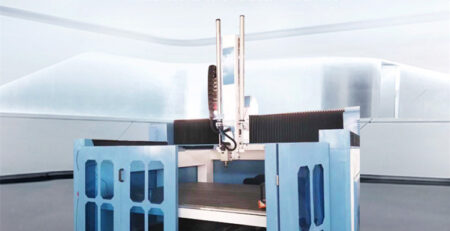

Tire mold laser cleaning machine

Traditional chemical cleaning agent cleaning method, high pressure water cleaning method, dry ice method, mechanical grinding, etc. Before using the laser cleaning equipment, the customer also tried to brush the adhesive layer on the surface of the plastic mold with a wire brush, but it did not work well. The cleaning effect of the wire brush is not obvious, and the glue on the surface of the plastic mold is difficult to clean. This kind of cleaning has the disadvantages of high labor intensity, low power, low safety factor and high cost. Laser cleaning can solve this problem well. Laser cleaning is the use of high-frequency high-energy laser pulses to irradiate the surface of the workpiece. The coating can instantly absorb the concentrated laser energy, so that the oil stains, rust spots or coatings on the surface can be evaporated or peeled off instantly, and the surface attachments or coatings can be removed efficiently at high speed. cleaning method, while the laser pulses with very short action time will not damage the metal substrate under the appropriate parameters.

The laser beam emitted by the laser cleaning equipment is irradiated on the surface of the plastic mold, and the impurities on the surface absorb the concentrated laser energy, causing it to evaporate instantly or peel off from the surface of the plastic mold. The laser cleaning equipment is simple to operate, easy to learn and use. In traditional cleaning methods, different personnel operations may cause different cleaning effects. However, by setting certain parameters for laser cleaning, the workpiece can be cleaned, and the cleaning effect is general.

Technology has changed lives. The traditional mode of tire cleaning is very troublesome, but since the advent of laser cleaning machines, tire cleaning has become easy, simple and convenient. The mold is an important tool used in the tire vulcanization process. The comprehensive deposition of rubber, compounding agents, and mold release agents (main pollutants are sulfides and inorganic oxides) used in the vulcanization process inevitably contaminates the mold. , silicone oil, carbon black, etc.), repeated use will cause part of the pattern to pollute the dead zone. Therefore, the mold must be cleaned regularly to ensure the cleanliness of its surface.

There are two traditional cleaning methods for tire molds:

mechanical cleaning

Physical sanding and dry sandblasting with manual emery cloth or steel wire, different combinations can be selected according to needs.

Advantage:

Proven technology widely used in the tire industry.

The operation is simple and easy, and the requirements for equipment and tools are low.

Shortcoming:

It will cause mechanical damage to the mold and shorten the life of the mold

Sandblasting can easily block the vent holes of the mold, and it takes a lot of work to clean the vent holes after sandblasting.

High labor intensity and long cleaning cycle

chemical cleaning

The main chemical cleaning methods are: organic solvent method, melting method, pickling method, alkali cleaning method, etc.

Advantages: easy to use, low cost

Disadvantages: Long-term use of the above methods will cause mold corrosion, which directly affects the appearance and quality of the product. At the same time, these pharmaceutical raw materials pollute the environment and damage the health of operators. Must be equipped with perfect labor protection measures and pollutant treatment equipment.

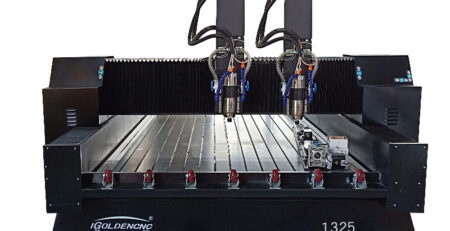

Laser cleaning machine

Fiber laser cleaning machine is a high-tech product for metal surface cleaning. It’s easy to install, with automatic focus and simple operation. No chemical reagents, media, dust and water are required for cleaning; it has the characteristics of small size, high speed, high precision and good stability. Good and other characteristics, the comprehensive index has reached the leading level.

Leave a Reply

You must be logged in to post a comment.