How to use six-sided drill Machine production line efficiency?

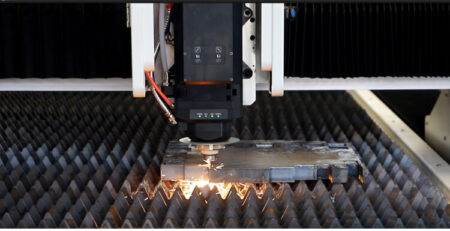

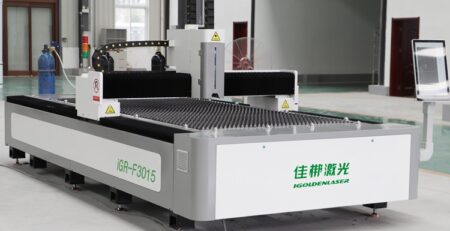

The complete set of equipment for the six-sided drilling production line includes three sets of CNC cutting machine, automatic edge banding machine, and numerical control side hole machine. The three processes of hole, slotting and material cutting save a lot of auxiliary time. It can process various shapes of plates such as arcs and special shapes, which is difficult for traditional woodworking machinery to do. CNC equipment has high precision, fast speed and good processing effect.

Six-sided drill Machine production line

The machine processing speed of the six-sided drilling production line is fast. After the plate is fixed, the machine automatically cuts according to the input plate size, without redundant manual operation, effectively improving the processing efficiency; optional automatic typesetting software, only need to input the plate size, the software typeset it Through optimization, the utilization efficiency of the board can reach more than 90%, which can improve the utilization efficiency of the board and reduce the cost of raw materials. The previous cutting equipment such as the push table saw requires two people to operate, and the workers need to keep turning the plate, which has high work intensity. One person can also operate multiple machines, and the cutting work intensity is low, thus saving labor costs; The plate cutting has no edge chipping phenomenon and the size is accurate, which provides an effective guarantee for the later installation.

Loading by forklift. Through automatic labeling and docking data, it is provided to the machining center for large plate nesting (ie, the cutting center for automatic loading and unloading).

Loading by forklift. Through automatic labeling and docking data, it is provided to the machining center for large plate nesting (ie, the cutting center for automatic loading and unloading).

2 It is manually sent to the intelligent connection for feeding, and the automatic edge sealing and drilling process is completed each time a single plate is fed.

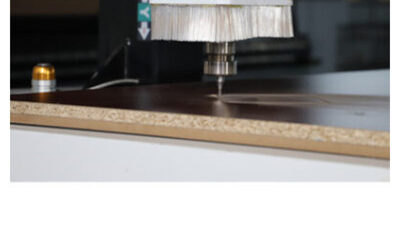

3 After the edge sealing process is completed, it will be transported to the intelligent drilling area, and automatically drilled and grooved.

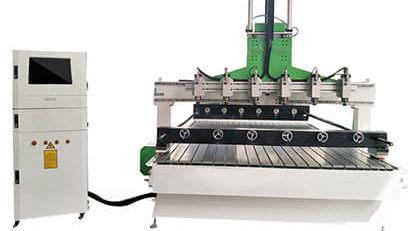

The intelligent connection system of edge banding and drilling is an intelligent and automatic production processing and conveying equipment designed to meet the needs of furniture production. Automatic labeling CNC cutting machine, main body of edge banding machine, pass-through six-sided drill, power conveying roller table, edge banding machine belt connection, translational belt conveyor, translational power roller table, multi-layer intelligent cache bin, PLC control system, etc. composition.

Highlights

High technology compact machine making possible to drill holes on 6 sides, groove top and bottom, route shapes in one process without necessary of turning panel. Continuous working for various batch sizes and patterns to fit complex production. High accuracy and processing effective, basically no complaints.

Long guiding rail with dual clampers. Cleaning device in between to remove possible chips and dust on workpiece surface for tightly grasping. Special design on bottom, clampers will fall down to make sure workpiece and the unloading table are at same level to prevent possible small scratch.

Two boring blocks and one 3.5kw main spindle on top processing unit; One boring block and one 3.5kw main spindle on bottom processing unit; Well arranged drills layout makes it possible to do mirror processing at the same time.

The accurate movement of each axis is ensured by the high quality servo motors. Fast and precise. Max travelling speed: X/U/Y/Z:135/135/75/30m/min

Leave a Reply

You must be logged in to post a comment.