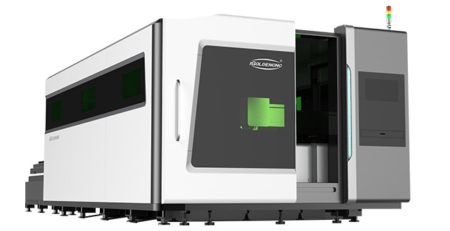

Full heat exchange film laser cutting machine

The fresh air total heat exchanger is a kind of ventilation facility that continuously provides high performance and high efficiency, ensuring to drive indoor air circulation to form a constant humidity space. Air circulation. It is a product that improves the quality of people’s living environment. The editor will introduce to you a piece of equipment today, which is the most important equipment in the production of total heat exchangers – total heat exchange film laser cutting machine.

What is total heat exchange membrane? As we all know, the total heat exchange core is the core component of the total heat exchanger, which determines the quality of the total heat exchanger, and the total heat exchange membrane is the core part of the total heat exchange core, which plays an important role in the filtration and exchange of air. effect. The total heat exchange membrane is a moisture-permeable porous fiber material or composite membrane, which is flexible, light, elastic, and extremely hydrophilic. With the maturity of technology, the application of total heat exchange cores has increased year by year, and in the production process of exchange cores, the cutting of the exchange membrane is bound to be inseparable, which also brings production pressure to many total heat exchanger manufacturers .

What is total heat exchange membrane? As we all know, the total heat exchange core is the core component of the total heat exchanger, which determines the quality of the total heat exchanger, and the total heat exchange membrane is the core part of the total heat exchange core, which plays an important role in the filtration and exchange of air. effect. The total heat exchange membrane is a moisture-permeable porous fiber material or composite membrane, which is flexible, light, elastic, and extremely hydrophilic. With the maturity of technology, the application of total heat exchange cores has increased year by year, and in the production process of exchange cores, the cutting of the exchange membrane is bound to be inseparable, which also brings production pressure to many total heat exchanger manufacturers .

What are the advantages of the full heat exchange film laser cutting machine?

- This model adopts a non-contact cutting method, and the edges are smooth and free of burrs

- Compared with traditional manual cutting, the cutting efficiency is greatly improved

- This model is equipped with a CCD visual recognition system, which can automatically locate the cutting position without manual intervention

- The model is equipped with automatic typesetting process, which greatly improves the utilization rate of raw materials

- The model has high cutting precision, suitable for cutting and cutting of various special-shaped patterns, and the operation is convenient and simple

Full heat exchange film laser cutting machine application industry

- Handicraft industry: exquisite patterns and characters are carved on wood, bamboo chips, ivory, bones, leather, marble, shells and other materials.

- Advertising industry: mainly used for two-color plate engraving, acrylic engraving and cutting, sign engraving, crystal, trophy engraving, authorization card engraving, etc.

- Leather garment processing industry: complex text and graphics engraving, cutting, engraving and hollowing out on synthetic leather, artificial leather, fabric and fur. Cutting, engraving, transcending fashion, and expressing individuality in the clothing, home decoration, gloves, handbags, shoes, hats, toys and car decoration industries.

- Model industry: make sand table building models and aircraft models.

- Packaging industry: engraving and printing rubber sheet, plastic sheet, double-layer sheet, die-cutting blade, etc.

- Other industries: engraving marks on decorative materials such as marble, granite, glass, crystal, paper cutting, greeting cards and other paper craft cutting

What are the advantages of laser engraving machine compared to mechanical engraving machine?

- Laser engraving machine is more efficient than mechanical engraving machine.

- The laser engraving machine can engrave finer lines and smoother edges.

- The processing materials of the laser engraving machine do not need to be fixed, while the materials of the mechanical engraving machine must be fixed.

- The laser engraving machine can process soft materials, including leather, paper, felt, etc. The mechanical engraving machine can only process hard materials, and soft materials are absolutely impossible.

Leave a Reply

You must be logged in to post a comment.