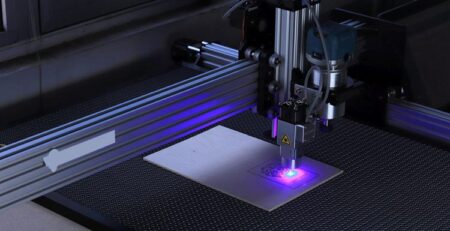

Laser Tube Cutting Machine_Laser Cutting Machine

In recent years, the development momentum of laser cutting equipment is very strong. Many customers have used laser series processing equipment. At present, laser cutting is widely used in the pipeline processing industry. Laser tube cutting machines on the market can be divided into two types: plate tube integrated machine and professional tube cutting machine. According to the cutting ability or function, it can be divided into single platform plate and tube integrated machine, exchange platform plate and tube integrated machine, professional laser tube cutting machine, semi-automatic laser tube cutting machine, and automatic laser tube cutting machine. The price of various products will vary, usually you will choose the right model according to your needs.

Advantage 1: save labor, improve production efficiency, and good cutting effect.

Advantage 1: save labor, improve production efficiency, and good cutting effect.

The traditional process of processing pipe workpieces requires first cutting with a sawing machine, then drilling holes with drills or punches, and then performing chamfering and deburring work. The various processes cannot be seamlessly connected, and the processing of pipes or workpieces in each process will actually result in one movement. Do a lot of useless work, wasting manpower and time costs. Laser cutting machine processing pipe is a one-time forming, 6 meters long pipe is placed on the machine, click start, all openings and cuts on the workpiece are formed at one time, and the finished product has no burrs.

The second advantage is that it is not affected by the mold, and can be cut into any shape, speeding up the research and development of new products of various enterprises.

Saw blade is the most commonly used pipe cutting link in traditional industrial pipe processing. The price of the saw blade is around 1000 yuan. Service life varies according to operator proficiency and frequency of use. In addition, during the cutting process, the blade should be cooled with cutting fluid to prevent the blade from cracking. After cutting, each factory has different options. For a useful drill press, a drill press is better for drilling long holes. For square holes and angled holes, it is not easy to machine. For useful punches, punches are more suitable for hollow workpieces of the same size. The distance between the single hole and the space should not be too large. Generally speaking, pipe fittings processed by conventional equipment are only suitable for rough machining of small batches. The laser pipe cutting machine can solve these problems very well, and all shapes made on the drawings can be processed on the laser pipe cutting machine.

Advantage three: reduce environmental pollution and noise pollution.

Various equipment in traditional machining workshops is very noisy. The workshop needs to communicate loudly and may be hard to hear. The cutting fluid used in the cutting process will also cause great pollution to the environment. Laser cutting machines do not have this phenomenon. The working sound of the laser cutting machine is very small, probably similar to the sound of a car idling, and it will not interfere with people’s communication.

Laser tube cutting machines use computer-aided design software for graphic design and import it into the cutting machine’s operating system to automatically cut and maximize the speed of manufacturing projects. Typically, the operating system contains a database with key information such as the material type, thickness and geometry of the pipe.

Advantages of Laser Tube Cutting Machines

High cutting precision and high efficiency

The real difference of laser pipe cutting machines lies in the cutting accuracy, which adopts chuck type and push type cutting methods, with high centering precision and processing precision; due to the improvement of modern laser cutting machines, it involves the industrial manufacturing of small diameter pipes. The application is greatly accelerated. The laser tube cutting machine can make corresponding adjustments according to these deformations to ensure the precision of the tube cutting, which is impossible for many traditional processes.

The laser pipe cutting machine can realize mass production, and all operations can be unified into one unit as a continuous operation process, which greatly reduces the logistics time. The standard pipe length is 6 meters, and the traditional processing method requires very heavy clamping, while laser processing can easily complete the clamping and positioning of several meters long pipes, making batch processing possible.

The laser tube cutting machine has flexible fiber laser transmission, compact cutting head structure, no reflective lens, basically maintenance-free and damage-free; powerful cutting function, four-jaw self-centering chuck, can cut square tubes, round tubes, rectangular tubes and various special-shaped tubes tube; the diameter and length of the processing tube can be customized (standard round tube diameter Φ30 ~160mm, length 6000mm); cost-effective, low cost of use, low follow-up maintenance cost; simple and easy-to-operate processing system, which can monitor processing status feedback in real time to ensure Processing is orderly.

Leave a Reply

You must be logged in to post a comment.