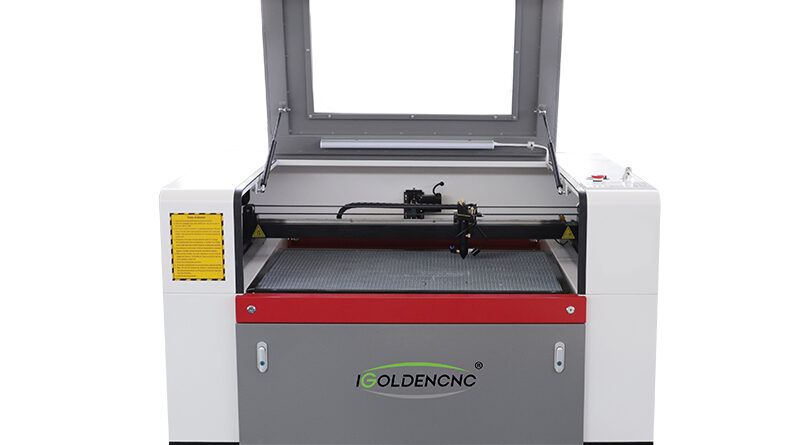

Metal and Nonmetal Laser cutting machine main process

2022 top rated CO2 hobby laser cutter machine is an entry level laser engraving & cutting system for hobbyists, small business, small shop, home business and home shop. Now the best hobby laser cutter for sale at affordable price.

Vaporization cutting.

Vaporization cutting.

During the laser gasification cutting process, the surface temperature of the material rises to the boiling point temperature so fast that it avoids the melting caused by heat conduction, so that some of the material vaporizes into vapor and some of the material is used as the effluent from the bottom of the slit. The stream blows away. Very high laser power is required in this case.

In order to prevent the material vapor from condensing onto the slit wall, the thickness of the material must not exceed the diameter of the laser beam. This processing is therefore only suitable for applications where it is necessary to avoid the exclusion of molten material. This processing is actually only used in the small field of use of iron-based alloys.

This processing cannot be used for materials such as wood and certain ceramics, which are not melted and are therefore less likely to recondense the material vapor. In addition, these materials typically require thicker cuts. In laser gasification cutting, the optimal beam focus depends on the material thickness and beam quality. Laser power and heat of vaporization have only a certain effect on the optimal focus position. In the case of a constant sheet thickness, the maximum cutting speed is inversely proportional to the material’s vaporization temperature. The required laser power density is greater than 108 W/cm2 and depends on the material, depth of cut and beam focus position. In the case where the thickness of the sheet is constant, assuming sufficient laser power, the maximum cutting speed is limited by the gas jet velocity.

Melt cutting.

In laser melt cutting, the workpiece is partially melted and the molten material is ejected by means of a gas stream. Since the transfer of material occurs only in its liquid state, this process is called laser melt cutting.

The laser beam is matched with a high-purity inert cutting gas to cause the molten material to leave the kerf, and the gas itself is not involved in the cutting. Laser melt cutting can result in higher cutting speeds than gasification cutting. The energy required for gasification is generally higher than the energy required to melt the material. In laser melt cutting, the laser beam is only partially absorbed. The maximum cutting speed increases as the laser power increases, and decreases almost inversely proportionally as the thickness of the sheet increases and the melting temperature of the material increases. In the case of a constant laser power, the limiting factor is the air pressure at the kerf and the thermal conductivity of the material. Laser melt cutting provides an oxide-free cut for the iron material and titanium metal. The laser power density that produces melting but less than gasification is between 104 W/cm2 and 105 W/cm2 for steel materials.

Oxidative melting cutting (laser flame cutting).

Melting and cutting generally uses an inert gas. If it is replaced by oxygen or other reactive gas, the material is ignited under the irradiation of a laser beam, and a strong chemical reaction with oxygen generates another heat source to further heat the material, called oxidative melting cutting. .

Due to this effect, for structural steels of the same thickness, the cutting rate obtainable by this method is higher than that of melt cutting. On the other hand, this method may have a worse cut quality than melt cut. In fact it produces wider slits, significant roughness, increased heat affected zone and worse edge quality. Laser flame cutting is not good when machining precision models and sharp corners (there is a danger of burning sharp corners). Pulse mode lasers can be used to limit thermal effects, and the power of the laser determines the cutting speed. In the case of a constant laser power.

Application of the Laser cutting machine

Metal and nonmetal laser cutting machine 1390 big size laser CO2 cutting bed, able to engrave and cut acrylic, wood, MDF, plywood, glass and many other non-metals and thin metals. Widely used in craft gifts, advertising, signs, furniture, clothes, decoration and other industries. Fast working speed, high precision.

Leave a Reply

You must be logged in to post a comment.