The Latest Overview of Automatic Furniture Making Machine

Automatic furniture making machine basically refers to electronic or computer CNC machines for manufacturing different furniture. These machines help to manufacture furniture products for various functions. For example, door, windows, tables, chairs, cabinets, stairs railings, office furniture, etc. You cannot shape wood structure and make a variety of furniture products for families and office settings. There are many types of automatic furniture making machine in these days now. These automatic furniture making machine have a lot of easy-to-use features that can help improve production level and quality in the main way. Use the right-wing furniture manufacturing machine, you can also improve your profits.

Automatic furniture making machine: CNC router

The CNC router is one of the most commonly used furniture manufacturing machines in the world. This automatic furniture making machine uses a computer digital control method to manage its functions. The use of digital control technology also improves the productivity, accuracy and efficiency of automatic furniture making machine. Therefore, it provides greater accuracy than traditional tools. The CNC router furniture machine is an indispensable machine of almost all furniture manufacturers.

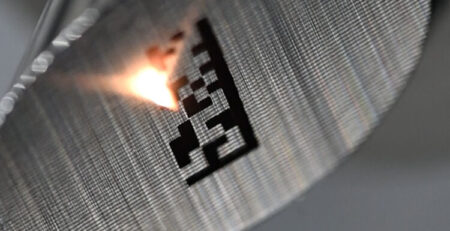

CNC routers with different configurations can achieve various furniture production processes. For example, cutting, engraving, drilling, milling, and bag, I want to introduce a digital control router for engraving complex 3D patterns or cylindrical furniture components.

ATC CNC Router with Automatic Tool Changer for furniture making

Automatic furniture making machine: Nesting CNC Machine

Similar to CNC routers, nesting CNC machine are also one of the most commonly used automatic furniture making machine in the industry. Nesting CNC machine are the best cutters suitable for panel furniture and custom furniture. However, different from the CNC router, the nesting CNC machine can be cut for a long time. Many furniture manufacturing plants use CNC nested furniture machine cutting and drill cabinet products. For example, kitchen cabinets, wardrobes, closets, shelves, etc.

The main difference between the CNC router machine and nesting CNC machine is that the CNC router is mainly used to engrave patterns on the furniture panel, but it is not suitable for huge cutting. Given that the nesting CNC machine is mainly used for cutting panel furniture and can be cut for a long time.

If you have sufficient budget, you can also add other features to nesting CNC machine. For example, automatic label, automatic loading, and unloading platform, double platform, two saws, drilling bags, etc.

Multi-process nested number control furniture making machine

Multi-process nesting CNC machines mainly include double-layer nesting CNC machine, three process nested number control machines, and four process nesting CNC machines. Depending on the quantity of the process, nesting CNC furniture making machines can be equipped with different spindle motors.

Each spindle can carry a tool so that when you need a knife, the corresponding spindle will automatically drop to work. The remaining spindles will stop and upgrade to standby, saving the trouble of manually changing tools. Therefore, four process nested population furniture manufacturing machines can achieve up to four processes. It is ideal for producing cabinets and cabinets.

In addition, you can replace a spindle of such a cabinet manufacturing machine with a borehole package to perform a drilling operation. In this case, multi-process nested CNC cabinet manufacturing machines can meet most of the cutting, engraving and vertical drilling requirements in furniture manufacturing. It significantly saves time and labor.

Linear ATC CNC Router machining Center

Automatic furniture making machine: edge banding machine

The edge banding machine is rough and there is no attractive. In addition, due to the production process, the panel will release formaldehyde by exposed edges. However, the edge banding machine can hide rough and ugly edges and also inhibit the release of formaldehyde. This makes the house more environmentally friendly and health.

Therefore, the edge banding machine is also one of the commonly used automatic furniture making machine. This automatic furniture making machine is mainly used for the edge accessory process of panel furniture. It falls into manual, semi-automatic and automatic type. The fully automatic edge lacing machine is better than the other two, regardless of the effect or efficiency. But the semi-automatic type is necessary for irregular edges.

Automatic Edge Banding Machine for Furniture Product

Automatic furniture making machine: wood drilling machine

Drilling machine is an indispensable process in furniture production. It is conducive to the subsequent mounting screws, hinges, and other connecting parts and assembly work. This makes timber drilling machines into important categories of furniture manufacturing machines. The CNC wooden rustier is better than the drilling machine because it is safer, efficient and accurate. The application of CNC wood rig not only reduces the customer’s production cost, but also improves production efficiency.

Furniture manufacturers designed for drilling process include nesting CNC with multi-head drill, side drills and six-sided drilling machines. The drilling effect and efficiency of different wood drilling machines are completely different.

Most CNC machines with rigid diamonds can be perpendicularly drilled during cutting. But if you want to drill on the side of the panel, the side rig is a perfect choice.

Six-sided CNC Drilling Machine

Automatic furniture making machine: vacuum press machine

From the current market, although the solid wood furniture is still loved by many consumers, the hotter and the door have also achieved more popularization. This is because customers have changed in personality, environmental health and cost performance.

Some customers may have special requirements for the color or wood grain of their furniture. The coating layer PVC film can meet these requirements. This PVC film has various styles of thickness, color, and grain. The hot original cabinet and the door are exquisite and stylish, easy to clean, and avoid scratching and falling off. High quality PVC film is also waterproof, muscle dust, flame retardant and zero-formaldehyde.

Automatic Bottom-heating Vacuum Laminating Machine

Furniture production line

Today, most furniture manufacturers provide a complete furniture production line, which contain many furniture manufacturing machines. For example, non-porous process cabinet produce solution, door production line, cabinet production line, etc.

Automatic furniture making machine in the furniture production line can be freely combined to meet different machining needs. For example, if you make a thermometer door, a vacuum press on the production line may be required. Free combination allows you to choose the right furniture production line for your factory, greatly improve efficiency and increase profits.

How to choose automatic furniture making machine production machine

After talking about so many furniture machine, do you know how to choose one? At present, many companies are good at manufacturing machinery development and production. By contacting them, you can find the exact type of furniture manufacturing machine you are looking for. Since these furniture machines appear at sufficient prices, you should have a picky method when you want to buy one of them.

Clear your processing requirements and budget

Although they are wooden furniture, different processes require different furniture manufacturers. Panel furniture, furniture production lines including various machines is the best choice. However, for personalized European or traditional Chinese style furniture, complicated engraving style, frame or handrails, will need a 4-axis wooden CNC router.

You need to choose a furniture machine based on your processing needs.

If you only make a cabinet, you can choose four nested CNC machines, edge straps, vacuum pressures, and side rigs.

If you make a hotter cabinet and door, you can select a linear ATC CNC machining center, an edge banding machine, polishing machine, a vacuum press machine.

In the case of making custom-free process furniture, you may need a non-porous process nested number of control machines, edge belts, vacuum pressures, and side drilling machines.

More importantly, you can also choose a sliding table saw, hinge drill, corner trimmer, and other auxiliary furniture manufacturing machines for the production line. If you have enough budget, nesting CNC machines can equip the drill set, automatic loading and unloading platform, suspecting working platform.

Conclusion

For furniture manufacturers, furniture making machine are definitely a valuable investment. Whether it is a single furniture machine or a complete furniture production line, it can greatly improve the efficiency and time and labor of furniture manufacturing. In addition, a person can operate 2-3 machines at the same time due to high automation levels and operation. This also helps to improve production efficiency. Finished furniture products have a variety of features such as high precision, fashion style, durability, etc.

To buy furniture makers, there are two main things to pay attention to. One is your own handling demand, and the other is to choose the right furniture manufacturing machine supplier.

The former can help you determine the required machine type and avoid buying an unsuitable machine with a high price. Due to different machines require different machines, you need to determine your own needs before purchasing. The latter asks you to filter carefully to prevent the quality of the furniture you buy unqualified, and there is no good after-sales service.

If you encounter any problems when buying furniture manufacturing machines, please feel free to tell me. I will help you choose the right furniture machine.

Leave a Reply

You must be logged in to post a comment.