Precision laser drilling machine_Precision fiber laser cutting machine

Precision laser drilling machine is one of the earliest practical laser processing technologies, and it is also one of the main application fields of laser processing. The principle of precision laser drilling is to drill objects through high power density pulses and short residence time of the heat source. Precision laser drilling machines are widely used in the processing of mobile phone products, and its process application and display can be seen from internal components to shells.

Compared with traditional drilling methods such as mechanical drilling process, electric spark discharge and electrochemistry, precision laser drilling machine is the cutting-edge technology of a new generation of intelligent optical technology, with essential differences and advantages. For example, micron-scale apertures can be processed on high melting point or high hardness material plates, or micron-scale deep holes can be processed on spinnerets of sapphire, ruby, diamond materials and chemical fiber materials. Precision machining tasks that are difficult or even impossible with traditional machining methods can be easily accomplished with the new precision laser drilling process.

Compared with traditional drilling methods such as mechanical drilling process, electric spark discharge and electrochemistry, precision laser drilling machine is the cutting-edge technology of a new generation of intelligent optical technology, with essential differences and advantages. For example, micron-scale apertures can be processed on high melting point or high hardness material plates, or micron-scale deep holes can be processed on spinnerets of sapphire, ruby, diamond materials and chemical fiber materials. Precision machining tasks that are difficult or even impossible with traditional machining methods can be easily accomplished with the new precision laser drilling process.

With the continuous innovation of laser technology, the laser beam with high energy density is highly concentrated in space, reducing the spot diameter to micron level or even smaller, so as to obtain a highly concentrated power density and complete the drilling task at the fastest speed. And the materials that can be used are very wide.

The advantages of precision laser drilling machine are as follows:

Fast punching speed and high efficiency; high punching precision, accurate positioning without deviation;

The punching outline is clear and three-dimensional, smooth and free of burrs;

The heat affected zone is small and will not cause deformation or damage to the workpiece. It is suitable for drilling of various materials such as brittle, hard and soft.

It is suitable for batch processing of high density and large number of holes;

No additional consumables are required during use, and no tool wear is required;

It can punch holes on irregular and difficult-to-machine inclined surfaces and curved surfaces;

The application of precision laser drilling machine in mobile phones is mainly the precision cutting or micro-hole precision machining of small parts such as metal or non-metal parts of mobile phones. Common application scenarios such as: laser drilling of FPC flexible circuit board inside mobile phone, laser drilling of mobile phone home button, laser drilling of mobile phone camera/flash, explosion-proof film/polarizer punching, mobile phone receiver/laser drilling and other microphones, dustproof Mesh laser drilling, etc.

The continuous breakthrough and innovation of precision laser drilling machines will continue to contribute to the development process of diversification, lightweight and thinning of mobile phones and the entire 3C electronics industry.

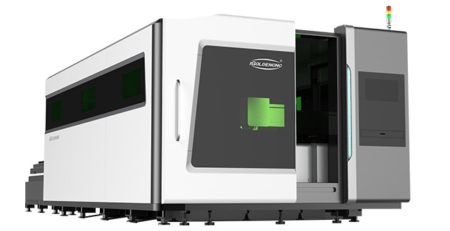

Recommended precision laser drilling equipment: precision fiber laser cutting machine

Flow Description:

- Adopt high-precision marble and heat-treated steel frame structure to ensure long-term stability of the equipment;

- The equipment has power, frequency, speed and other functions to improve the cutting effect;

- The motion mechanism adopts linear motor, which has fast response speed and high sensitivity, which can realize short-stroke high-speed motion and high dynamic performance;

- High resolution, can achieve higher positioning accuracy;

Applicable materials: used for precision laser cutting and precision laser drilling of various metal sheets such as electronic industry, precision machinery, medical equipment, and terminal technology products.

Applicable materials for precision fiber laser cutting machine:

Metals (including rare metals), engineering plastics, electroplating materials, paints, coatings, plastics, rubber, epoxy resins, ceramics, plastics, ABS, PVC, PES, steel, titanium, copper and other materials, electrical appliances, communication products, sanitary Sanitary ware, tools, accessories, knives, glasses and clocks, jewelry, auto parts, luggage buckles, cooking utensils, stainless steel products and other industries.

Application industry:

Mobile phone buttons, plastic translucent buttons, electronic components, integrated circuits (IC), electrical appliances, communication products, sanitary ware, tools, accessories, knives, glasses and clocks, jewelry, auto parts, luggage buckles, cooking utensils, stainless steel products and other industries.

Leave a Reply

You must be logged in to post a comment.