Process Analysis Of Optical Metal Laser Cutting Machines

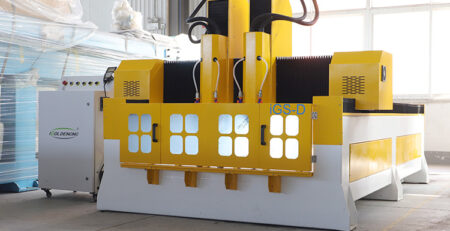

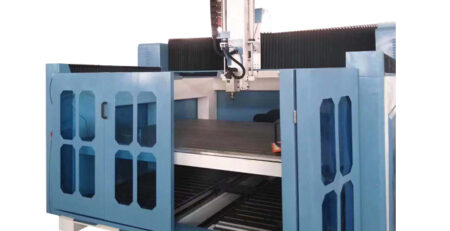

Metal laser cutting machines is one of the most researched areas of fibre laser application. It can handle complex cuts with impressive edge quality. The china CNC fiber laser cutting machine can achieve a highly automated processing process by connecting to a computer. Laser cutting technology can help producers improve processing efficiency, meet more customized demands of more customers, accurately manufacture, almost any shape of the sheet or metal plate. Whether you need 2D or 3D laser cutting services

Metal laser cutting machines is to focus the laser light emitted from the laser into a high power density laser beam through the optical path system. The laser beam irradiates the surface of the workpiece to make the workpiece reach the melting point or boiling point, and the high-pressure gas coaxial with the beam blows away the molten or vaporized metal. As the relative position of the beam and the workpiece moves, the material will eventually form a slit, so as to achieve the purpose of cutting.

There are three possible reasons that affect the cutting process, parameter settings, external accessories settings, and gas assist.

Parameter setting

Speed: If the cutting speed is too fast, the burning will be incomplete and the workpiece will not be cut through, and if the cutting speed is too slow, it will lead to excessive burning, so the speed will be increased or decreased according to the effect of the cutting surface.

Power: The energy used for cutting different plate thicknesses is not the same. As the thickness of the sheet increases, the required power also increases.

Automatic following system: Before cutting the sheet, the must use a calibration system, otherwise it will lead to poor cutting results. (The capacitance value of different metal materials is different. Even if the same material has the same thickness, the capacitance value is different), and then every time the nozzle and ceramic ring are replaced, the machine must use a calibration system.

Focus: After the is launched, the beam focused on the nozzle mouth by diffusion has a certain diameter, and the nozzle we use when cutting the bright surface is relatively small. In addition to external factors, if our focus is adjusted too large, it will lead to The light spot hits the cutting nozzle, which directly causes damage to the cutting nozzle and changes in the direction of the airflow, thus affecting the cutting quality. Excessive focus adjustment may also cause the nozzle to become hot, affecting the follow-up induction and unstable cutting. Therefore, we should eliminate external factors first, and then find the maximum focus value that the nozzle size can withstand, and then adjust it.

Nozzle height: Bright surface cutting has high requirements on beam propagation, oxygen purity and gas flow direction, and the nozzle height will directly affect the changes of these three points, so we need to adjust the nozzle height appropriately when cutting with high power. The lower the nozzle height is, the closer it is to the plate surface, the higher the beam propagation quality, the higher the oxygen purity, and the smaller the gas flow direction. Therefore, the lower the nozzle height during the cutting process without affecting the induction, the better.

External accessory settings

Optical path: When the laser is not emitted from the center of the nozzle to cut the plate, the edge of the cutting surface will have a good cutting effect and a poor effect.

Material: Sheets with clean surfaces cut better than sheets with dirty surfaces.

Optical fiber: The attenuation of the power of the optical fiber and the damage of the optical fiber head lens will lead to poor cutting effect.

Lens: The cutting head of has two types of lenses, one is the protection lens, which functions to protect the focusing lens and needs to be replaced frequently, and the other is the focusing lens, which needs to be cleaned or replaced after working for a long time, otherwise the cutting effect will be deteriorated.

Nozzle: Single-layer nozzle is used for melting cutting, that is, using nitrogen or air as auxiliary gas, for cutting stainless steel and aluminum plate and other materials. The double-layer nozzle uses oxidation cutting, that is, oxygen or air is used as auxiliary gas, which can speed up the oxidation process and is used for cutting carbon steel and other materials.

Gas assist

Oxygen: It is mainly used for carbon steel and other materials. The smaller the thickness of the carbon steel sheet, the better the cutting surface texture, but it cannot improve the cutting speed and affect the efficiency. The higher the air pressure, the larger the kerf, the worse the cutting pattern, and the easier it is to burn the corners, resulting in poor cutting effect.

Nitrogen: mainly used for materials such as stainless steel and aluminum plates. The higher the air pressure, the better the cutting surface effect. When the air pressure exceeds the required air pressure, it is a waste.

Air: It is mainly used for thin carbon steel, stainless steel and aluminum plate and other materials. The larger the other, the better the effect. When the air pressure exceeds the required air pressure, it is a waste.

Product positioning: thick plate cutting, especially high-precision plate processing, is mainly for manufacturers requiring . high precision and high efficiency. According to statistics, fiber laser cutting machine will replace most of the CO2 laser cutting machine market.

Leave a Reply

You must be logged in to post a comment.