What can the laser cleaning machine clean?

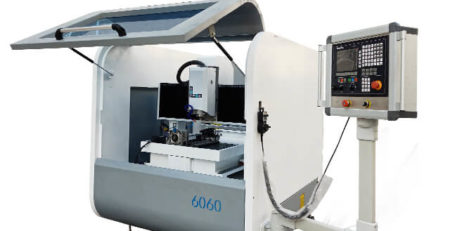

The laser cleaning machine uses high-frequency high-energy laser pulses to irradiate the surface of the workpiece, so that the oil stains, rust spots or coatings on the surface can be evaporated or peeled off instantly. the process of. .It has the characteristics of no damage to the base of the parts, no consumables, energy saving and environmental protection, etc. It meets the cleaning requirements of complex modeling and fine positioning in the field of industrial processing, and achieves higher cleanliness cleaning effect and lower comprehensive cost production benefits.

The laser cleaning equipment produced by Jiabang Laser is a new generation of surface treatment high-tech products, which are easy to install, simple to operate and have a high degree of automation. Simple to operate, power on, and clean without chemicals, media, dust and water. It can be cleaned according to the curved surface, and the cleaning surface is clean. Stains, dirt, rust, coatings, coatings and oxide layers are widely used in marine, auto repair, rubber molds, high-end machine tools, rails, environmental protection and other industries.

The laser cleaning equipment produced by Jiabang Laser is a new generation of surface treatment high-tech products, which are easy to install, simple to operate and have a high degree of automation. Simple to operate, power on, and clean without chemicals, media, dust and water. It can be cleaned according to the curved surface, and the cleaning surface is clean. Stains, dirt, rust, coatings, coatings and oxide layers are widely used in marine, auto repair, rubber molds, high-end machine tools, rails, environmental protection and other industries.

The main driver for laser cleaning applications is the market demand for non-toxic, non-abrasive cleaning methods that can be used as an alternative to previously used chemical cleaning, hand cleaning and abrasive jet cleaning methods.

Laser cleaning application:

When the metal is wet, it reacts with water to form ferrous oxide, thereby rusting. This rust can degrade the metal, making it unsuitable for many applications.

On the other hand, due to the heat treatment process, an oxide layer is formed on the metal surface, which can discolor the metal surface and hinder subsequent finishing operations.

The presence of dirt and other contaminants increases the resistance of the anode, causing more battery drain.

The presence of contaminants also shortens the life of the anode by increasing the rate of consumption in the smelting process.

Preparing for metal bonding

In order to improve process stability, surface adhesion and better welding quality, the surfaces of the metal materials to be joined must be prepared before welding and other joining techniques are applied.

Without the necessary cleaning of metal surfaces, joints and seams are prone to degradation, increased wear and even catastrophic failure.

Pre-brazing treatment

Helps remove ferrous and non-ferrous metals, lubricants and other contaminants from metal and aluminum surfaces in preparation for high-quality welding.

It also ensures smooth and non-porous brazing seams.

Partial removal of coating

It can be used on almost all surface types, whether chemical anodizing, oxides or organic coatings.

Laser cleaning in automotive and other industries removes coatings and paint while maintaining substrate integrity.

Selective paint removal

The use of lasers for polishing, surface cleaning and coating removal is rapidly expanding. Depending on the application, the pulse frequency, energy, and wavelength of the laser must be precisely selected to clean, polish, and ablate the target material. At the same time, any form of damage to the substrate must be prevented. At present, laser cleaning technology is mainly used for cleaning small parts. Of course, this technology is also highly likely to be suitable for cleaning large surfaces and large equipment/structures. With the current progress in the field, these visions are expected to become a reality in the near future.

Leave a Reply

You must be logged in to post a comment.