What Metal Materials Can The Steel Plate Laser Cutting Machine Cut?

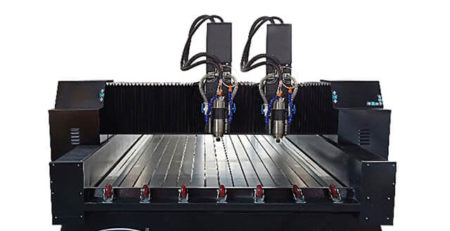

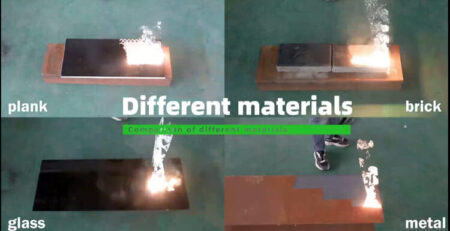

Steel plate laser cutting machine is more and more widely used in various industries, mainly because of its versatility. Sheet metal laser cutting can cut various metals, foam, wood, cork, paper, acrylic, and other materials, When using a custom metal laser cutting, you should understand the characteristics of the material you are cutting. LXSHOW will show you what materials the CNC metal laser cutter can and cannot cut.

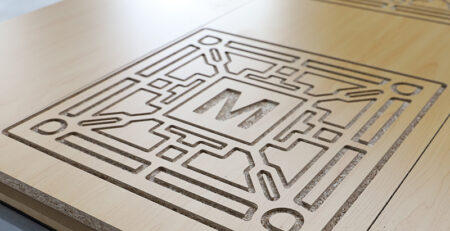

Steel Plate Laser Cutting Machine

Materials that can be cut:

Materials that can be cut:

1. Carbon steel. When the optical steel plate laser cutting machine uses oxygen as processing gas, the cutting edge will be slightly oxidized. When the thickness is up to 4mm, nitrogen can be used as processing gas for high-pressure cutting. In this case, the cutting edge will not be oxidized. If the thickness of the plate is more than 10 mm, the special plate can be used for the laser of the steel plate laser cutting machine, and the surface of the workpiece can be oiled in the processing, which can get better results.

2. Copper and brass. Both materials have high reflectivity and excellent thermal conductivity. Brass with thickness less than 1mm can be cut with nitrogen; copper with thickness less than 2mm can be cut with oxygen. Copper and brass can only be cut when a “reflection absorption” device is installed on the system. Otherwise the reflection will destroy the optical components.

3. Stainless steel is the most widely used in all industries. When cutting stainless steel with optical fiber laser cutting machine, nitrogen is used to get the edge without oxidation and burr without influence of edge oxidation. Coating the oil film on the surface of the plate will get better perforation effect without reducing the processing quality.

4. Aluminum. For the fiber laser cutting machine, although it has high reflectivity and thermal conductivity, aluminum with thickness less than 6mm can be cut, which depends on the alloy type and laser capacity. When cutting with oxygen, the cutting surface is rough and hard. When nitrogen is used, the cutting surface is smooth. Pure aluminum is very difficult to cut because of its high purity. It can only be cut when the “reflection absorption” device is installed on the fiber laser cutting machine system. Otherwise the reflection will destroy the optical components.

5. Titanium. Titanium plate is cut with argon and nitrogen as processing gas. Other parameters can refer to nickel chromium steel.

Steel plate laser cutting machine belongs to the category of metal cutting machine, so it can only be used to process metal, not non-metal materials, such as stone, cloth, leather and other materials. The reason is that the wavelength range of the fiber laser cutting machine is no longer within the absorption range of this type of material, or it is not suitable for absorption and can not achieve the desired effect.

carbon steelstainless steel

Secondly, the fiber laser cutting machine can not cut the density plate. The fiber laser cutting machine belongs to thermal processing. Cutting the density plate will cause combustion, so that the cutting edge will burn, unable to meet the cutting requirements. This type of materials are mainly raw materials of fiberboard, wood fiber and plant fiber, and some are artificial board made of urea formaldehyde resin and adhesive. These types of materials belong to the category of density plate, which can not be processed by fiber laser cutting machine at present.

Although fiber laser cutting machines have many excellent features, there are still many materials that cannot be cut. What materials cannot be cut by steel plate laser cutting machine?

First of all, we need to be clear that the fiber laser cutting machine belongs to the category of metal cutting machine, so it can be used to process metal. But for the non-metal materials such as cloth, leather, it is not the better choice.

Secondly, the fiber laser cutting machine cannot cut the MDF, which mainly include fiberboard, wood fiber, and plant fiber, and some materials are made of urea-formaldehyde resin and artificial board made of adhesive. Because fiber laser cutting machine is belong to hot-processed. It will cause burning and burn the cutting edge, therefore it fail to meet the perfect cutting requirements. Therefore, these types of materials are currently not process with fiber laser cutting machines.

There are also some highly reflective materials. Since these materials are not within the ideal absorption range of these materials for the laser wavelength, some energy will be reflected to burn out the protective lens. Therefore, these types of materials are also currently not process with fiber laser cutting machines.

Steel plate laser cutting machine is the most important application technology in the laser processing industry. It is also the earliest and most used processing method in laser processing. Because of its many advantages, it has been widely used in automobile manufacturing, aviation, shipbuilding, railway equipment, industrial automation, national defense, building materials and other industries. With the advantages of accurate, fast, simple operation and high degree of automation, laser cutting has become the first choice for manufacturers in the above industries to improve metal processing efficiency.

Leave a Reply

You must be logged in to post a comment.