Who Makes the Best Fiber Laser Cutting Machine

What is the Flatbed Fiber Laser Cutting Machine?

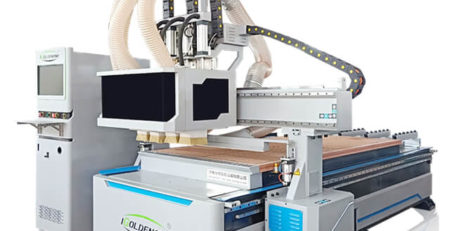

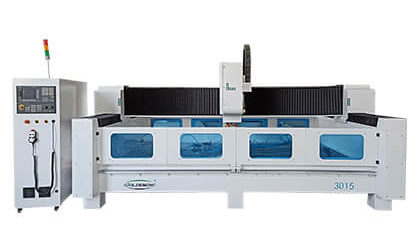

Flatbed Fiber Laser Cutting Machine, equipped with 1000w-12000w fiber laser, can cut 0-25mm thick carbon steel plate, 0-20mm thick stainless steel plate, aluminum plate, 0-12mm thick copper plate, standard working area is 1500*3000mm, can be upgraded It is an independent cabinet with built-in air conditioner for 1500*4500mm, 2000w and above power, and can be installed with a side rotation device to upgrade to a dual-use fiber laser cutting machine.

Who Makes the Best Fiber Laser Cutting Machine

Laser technology, together with computer technology, semiconductor technology, and atomic energy technology, is one of the world’s four great inventions in the 20th century and has had a huge impact on the development of the entire society. The laser is widely used in all walks of life because of its good directivity, monochromaticity, and high energy concentration. From daily necessities, food, housing, and transportation, to all aspects of processing and manufacturing in the industrial field, to medical beauty, lasers are everywhere, affecting all aspects of public life. From the perspective of the development of a country’s laser industry, the overall industrial manufacturing level can be seen to a certain extent.

Description:

The square tube welding bed is welded with a thick rectangular tube with a diameter of 200*200mm. The bed weight can reach 1T. The bed body is annealed and milled by a large gantry to accurately drill all installation basic holes at once.

Higher tensile strength and dimensional stability. Effectively improve the accuracy of the bed, reduce the processing error of the workpiece. Increase the resistance and stability of the guide rail.

It reduces the loss of the equipment when it is used. It keeps the precision of the cheap laser cutter for a long time and does not deform for 20 years. The affordable laser cutter has good stability and reduces the processing errors caused by the vibration of the bed.

★ High precision. After manual aging, solution treatment and finishing, the beam has good integrity, rigidity, toughness and ductility.

★ Fast speed. Aluminum alloy has the features of light weight and strong rigidity, which is conducive to high-speed movement during processing, and high flexibility is conducive to high-speed cutting of various graphics on the basis of high precision.

★ High efficiency. The lighter weight beam can ensure the rapid operation of the flatbed laser cutting machine, improve the processing efficiency, and at the same time ensure the processing quality.

Not only can the high-speed operation of the laser cutting machine be guaranteed, but also the accuracy and efficiency of the laser cutting processing.

Effectively improve the service life and accuracy of the cheap laser cutter, reduce time cost and reduce time loss. And after using the same time limit, the aluminum beam can ensure the cutting accuracy to the greatest extent, and at the same time it can alleviate the kinetic energy of laser head during high-speed movement.

Leave a Reply

You must be logged in to post a comment.