3D Fiber Laser Cutting Machine Cutting Effect?

Fiber laser tube cutting machine is one of the latest developments in laser cutting technology, offering unprecedented speed and accuracy to the metal fabrication industry. But like most terms in the fabrication industry, fiber laser cutting sounds very complex. So what exactly is it?

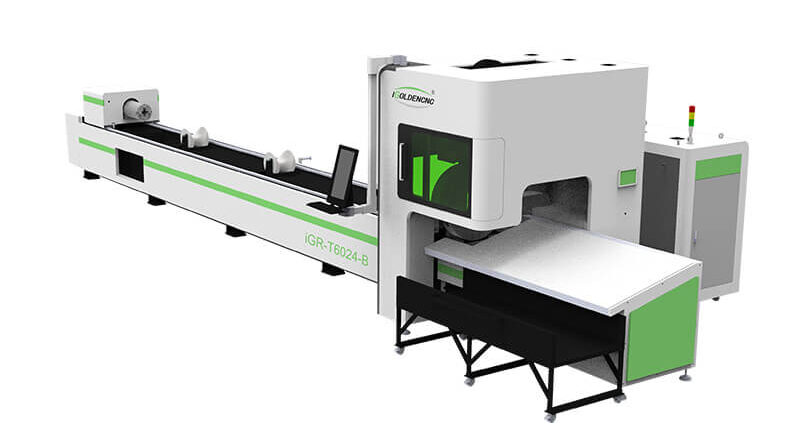

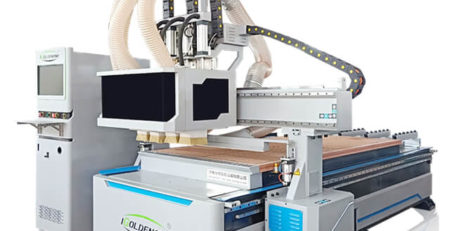

3D Fiber Laser Cutting Machine

A 3d fiber laser cutting machine uses active optical fibers to create a laser beam and a transport fiber to transmit this to the machine’s cutting head. This super hot laser is condensed down to a narrow beam and is used to cut through metals of various thicknesses.

There is no scratch on the workpiece surface. The mechanical part of the laser cutter head has no contact with the workpiece, and will not scratch the workpiece surface in the work;

The incision is smooth and flat, and the slope is small. The incision has no mechanical stress, no shear burr, no need for subsequent processing;

The plate is not deformed. Small cutting heat affected zone, small plate deformation, narrow slit (0.1mm~0.3mm);

Sample high precision, small error. CNC programming, can process arbitrary plane graph, can cut the whole board with a large format, no need to open mold, economical and time-saving.

Remax medium power 3000W laser cutting machine, for example, can achieve 8mm carbon steel bright cutting, 6mm stainless steel slag-free cutting.

6000W laser cutting machine, can achieve 12mm carbon steel bright cutting, 25mm carbon steel quality cutting, 30mm carbon steel limit cutting.

12000W laser cutting example, can achieve 40mm ultra-thick stainless steel limit cutting, 20mm carbon steel bright surface cutting that is no problem.

Advantages and Benefits of tube laser cutting machine:

1. Fiber laser electrical to optical conversion efficiency is high, conversion efficiency of more than 30%,greatly reduce the power consumption, save operation cost, achieve the highest production efficiency;

2. The operation of the laser only requires power, no need to generate additional gas laser, with the lowest operating and maintenance costs;

3. Fiber laser by semiconductor module and the redundancy design, resonant cavity free optical lens, does not require bootstrap time, with adjustment free, maintenance free, the advantages of high stability, reduce the cost of spare parts and maintenance time, which is unmatched by traditional laser;

4. Fiber laser output wavelength of 1.064 microns is 1 / 10 of the CO2 wavelength, the output beam quality, high power density, is very conducive to the absorption of the metal material, has excellent cutting and welding ability, so that the least cost of processing;

5. The whole routing optical fiber transmission, does not need the complex mirror and so on the light guiding system, the light path is simple, the structure is stable, the outside light road maintenance free;

6. The cutting head contains a protective lens, the focusing mirror and other precious consumable few consumption;

7. The light through the optical fiber are derived, the design of mechanical system is very simple and very easy to work with the robot or multidimensional integration;

8. After a gate coupled with laser multi machine, light through the optical fiber, divided into multi Taiwan work at the same time, the function is easy to expand, upgrade convenient and simple;

If you are interested in purchasing a 3d fiber laser cutting machine, we know it is not an easy decision. This can be a costly decision. However, at Moore Machine Tools we can help you choose the right machine that will help benefit your business. Our igoldencnc machines offer the most cost-effective technology and you will find that they will provide you with a great return on your investment.

Leave a Reply

You must be logged in to post a comment.