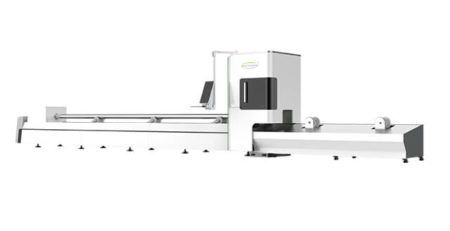

Affordable 5 Axis CNC Router Machines

Affordable 5 axis CNC router machines can work on foam, MDF, Acrylic, wood, and the soft metal, you can make different surface carving, arc-surface milling, bend surface machining for 4D 5D jobs: such as auto parts and aircraft structural parts, special shaped arts, Car mould, bended doors or cabinets etc modern molds processing. Because of 5 axis cnc router machines with high cost, so it suitable for medium and large wood foam enterprises.

5 Axis CNC Router Machine Types

5 axis CNC machine has three types of structure and movement configuration. When these two types are combined, nine 5 axis CNC machines of different structure types are obtained. 5-axis machining centers can be divided into five-axis linkage machining center, five-axis CNC machining center, five-axis precision machining center, five-axis high-speed machining center, small five-axis machining center, high-precision five-axis machining center, five-axis CNC router machine, vertical five-axis machining center.

As advanced CNC equipment, 5 axis CNC machining center or CNC router is designed specifically for complex curved surfaces. It is widely used in aviation, aerospace, automotive, military, scientific research, precision instruments, high-precision medical equipment, and other industries. It can process an extensive range of materials, such as wood, metals, stones, plastic, styrofoam, composites, etc.

What is 5 axis CNC machining?

Five axis CNC machining refers to the CNC processing in which the tools can work in 5 different directions simultaneously. Compared with the basic 3 axis machining, the five-axis CNC machining is more flexible and variable. The 5 axes refer to X+Y+Z+A (rotates around X)+B (rotates around Y), X+Y+Z+A+C (rotates around Z), or X+Y+Z+B+C.

IGOLDENCNC mainly provides the 5 axis CNC router machine and 5 axis machining center that works on X+Y+Z+A+C. A 5 axis router machine is an upgraded machine of regular 3 or 4 axis CNC routers. It is able to carve on a workpiece in five different faces simultaneously. Same as other CNCs, a 5 axis router operates on 3 primary axes of X, Y, Z. Besides, it can rotate its tools by two additional axes, A and C. This ensures the 5 axis router process more directions of the workpieces without adjusting them manually.

5 Axis CNC Router Machine Working Principle

First, let’s learn something about “axis”:

X-axis: front to back.

Y-axis: left to right.

Z-axis: up and down.

A, B or C axis is corresponding to the rotation axis of X, Y and Z axes.

Five axis: X-Y-Z-A-B, X-Y-Z-A-C, X-Y-Z-B-C (The spindle can be rotated left and right with 180 degrees around.) Five axis CNC machines move a part or tool on five different axis at the same time via CNC programming. 3 axis CNC machines move a part in two directions with X axis and Y axis, and the tool moves up and down with Z axis. Five axis CNC machines can rotate on two additional rotary axis (A aixs and B axis) which will help the tool to approach the part from all directions.

Five-axis linkage machining technology refers to the processing technology that a complex shape surface needs to use 5 independent axes to perform numerical control interpolation movement together to obtain a smooth and smooth surface. The number of axes for five-axis simultaneous machining refers to the number of axes that need to move independently when processing the same surface, rather than the number of controllable axes owned by the CNC. Although theoretically any complex surface can be expressed by X, Y, Z three-axis coordinates, the actual machining tool is not a point, but an entity with a certain size, in order to avoid the occurrence of tool and processing when processing the space distorted surface The interference between the surfaces and to ensure the consistency of the cutting conditions at each point on the surface require adjustment of the angle between the tool axis and the surface normal in the 2D direction. Compared with the three-axis linkage, the five-axis linkage can reduce the machining error and surface roughness to 1/3~1/6.

5 Axis CNC Router Machine Applications

5 axis CNC machine is designed to deliver high speed and highquality cuts for a wide range of materials, including but are not limited to wood, plastics, non ferrous metals and other composites. The CNC machine will provide various new applications including:

1. Edge trimming of thermoformed plastic, molded plastic and composite parts. The flexibility of the CNC machine creates the ability to provide high quality finishing and edge trimming on many manufactured plastic items.

2. Deep cavity mold making. On three-axis machines deep cavity mold making requires that you have longer tools to be able to reach deep enough. Having longer tools results in the user having to reduce cutting speed to prevent breakage. With the added movement provide by 5 axis machining, shorter tools can be used, and your cutting speed can be increased.

3. Molded plywood chairs and decorative furniture parts. The machine allows for unique shaping and molding of various materials, allowing you to make your creative and dynamic designs a reality.

4. Detailed 3D carvings. The increase in movement of the cutting tool on the machine allows it to carve intricate designs into a piece of material. It allows you to capture the fine details of your design in the job you are cutting.

Leave a Reply

You must be logged in to post a comment.