CNC Router Machine for Sign Making

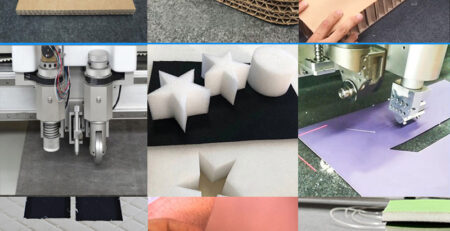

CNC router machines for sign making can cut and engrave a variety of materials, including wood, plastics, metals, and composites. They are commonly used to create signs for businesses, schools, and public spaces, as well as for advertising and promotional materials.

In addition to cutting and engraving, CNC router machines for sign making can also perform other operations such as drilling, grooving, and pocketing. This makes them highly versatile and capable of creating a wide range of sign designs and styles.

One advantage of using a CNC router machine for sign making is that it allows for precise and consistent cuts to be made, resulting in signs that are uniform in size and shape. CNC machines can also cut intricate designs and patterns with ease, allowing for more complex and unique sign designs.

CNC router machine for sign making is a highly efficient and versatile machine that can greatly improve the speed, accuracy, and quality of sign making projects. With the ability to cut and shape materials with precision and accuracy, CNC machines have revolutionized the sign making industry and opened up a world of design possibilities for sign makers and designers.

CNC wood sign making machine

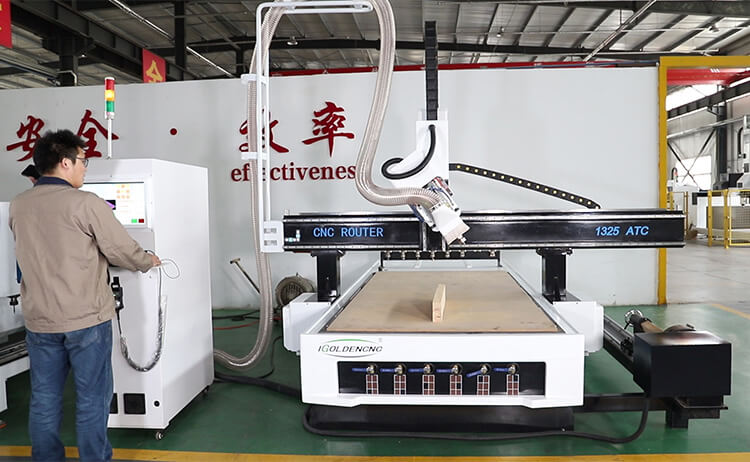

A CNC wood sign making machine is a computer-controlled machine specifically designed for creating wooden signs with precision and efficiency. It utilizes CNC technology to automate the cutting, carving, and engraving processes, allowing for the production of custom and detailed wooden signs.

Here’s an overview of the features and benefits of a CNC wood sign making machine:

- Design and Programming: The first step in creating wooden signs with a CNC machine is to design the sign digitally using CAD (Computer-Aided Design) software. The software allows you to create custom designs, incorporate text, logos, and other graphics. Once the design is complete, it is converted into machine-readable code through CAM (Computer-Aided Manufacturing) software.

- Material Selection and Preparation: CNC wood sign making machines are compatible with various types of wood, such as solid wood, plywood, MDF (Medium-Density Fiberboard), and more. The choice of material depends on factors like the desired finish, durability, and budget. The selected wood is then prepared by cutting it to the appropriate size and smoothing the surface if necessary.

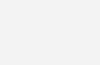

- CNC Routing and Engraving: The prepared wooden panel is secured to the CNC machine’s worktable, and the CNC router is equipped with a suitable cutting tool. The machine then follows the programmed instructions to precisely cut, carve, and engrave the design onto the wood surface. This includes cutting the outer shape of the sign, carving text and graphics, and creating decorative elements.

- Customization and Detailing: A CNC wood sign making machine offers great flexibility in customization and detailing. It can create intricate patterns, add 3D effects, incorporate beveled edges, and even perform V-carving for a three-dimensional look. The machine’s precise control allows for consistent and accurate replication of designs, ensuring high-quality results.

- Efficiency and Productivity: CNC wood sign making machines significantly increase productivity and efficiency compared to manual sign-making processes. The automation and precision of the machine enable faster production, eliminate human errors, and allow for batch processing. Multiple signs can be created in a single setup, reducing production time and labor costs.

- Versatility: CNC wood sign making machines can handle a wide range of sign types, sizes, and styles. Whether it’s outdoor signs, indoor signs, directional signs, nameplates, or decorative signs, the machine can accommodate various design requirements. It can work with different wood thicknesses and easily switch between cutting, carving, and engraving operations.

- Scalability and Replication: CNC machines are ideal for scaling up sign production. Once the initial design and programming are complete, the machine can replicate the same sign design with precision, ensuring consistency across multiple pieces. This scalability makes it suitable for sign-making businesses or projects that require large quantities of signs.

It’s important to note that the specific features and capabilities of CNC wood sign making machines may vary depending on the model and manufacturer. Different machines may offer different work areas, spindle options, tool changers, and control systems. Therefore, it’s recommended to assess your specific sign-making requirements and consult with suppliers or manufacturers to select the most suitable CNC wood sign making machine for your needs.

A plastic sign making machine is a type of CNC (Computer Numerical Control) machine that is used for cutting and engraving different types of plastic materials to create signs. These machines use computer-aided design (CAD) software to precisely control the cutting tools, allowing for accurate and intricate designs to be created.

There are different types of plastic sign making machines available, including laser engraving machines, CNC routers, and vinyl cutters. Each machine has its own advantages and disadvantages, and the choice of machine depends on the specific needs and requirements of the sign making project.

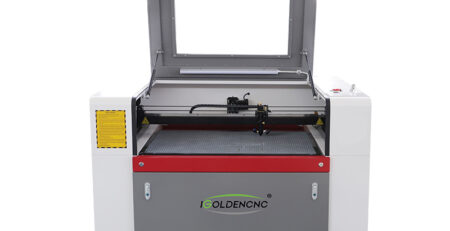

Laser engraving machines use a high-powered laser beam to engrave or etch the surface of the plastic material. This type of machine can create highly detailed and precise designs, and is often used for small-scale sign making projects.

CNC routers use cutting tools to cut and shape the plastic material. This type of machine can create more complex designs and larger signs, and can also be used to cut other materials such as wood and metal.

Vinyl cutters use a blade to cut vinyl sheets into lettering and shapes, which can then be applied to a sign. This type of machine is often used for creating simple signs with text and basic shapes.

When choosing a plastic sign making machine, it is important to consider factors such as the size and thickness of the plastic materials being cut, the level of precision required, and the speed and efficiency of the machine. It is also important to consider the compatibility of the machinewith various software programs and operating systems, as well as the availability of accessories and additional features.

Some additional features and accessories that may be available for a plastic sign making machine include:

- Automatic tool changers: These systems can automatically change cutting tools during the cutting process, allowing the machine to perform multiple operations without the need for manual intervention.

- Dust collection systems: These systems can help to reduce the amount of debris generated during the cutting process, which can improve air quality and reduce the risk of respiratory problems for operators.

- Vacuum tables: These tables use suction to hold the plastic material in place during the cutting process, which can help to reduce the risk of movement or vibration that may affect the accuracy of the cuts.

- Rotary devices: These devices can be used to cut and shape cylindrical objects such as posts and columns.

- Automatic tool calibration: This feature allows the machine to automatically calibrate the cutting tools for improved accuracy and efficiency.

Overall, a plastic sign making machine is a versatile and efficient machine that can greatly improve the speed, accuracy, and quality of sign making projects. With the ability to cut and shape plastic materials with precision and accuracy, these machines have revolutionized the sign making industry and opened up a world of design possibilities for sign makers and designers.

Comment (1)

[…] CNC Wood Signs Making Machine […]