Some knowledge about CNC Wood Router Table

How to protect the CNC wood router table during the processing?

In the engraving process of CNC machine, due to incorrect use of fasteners or placement of non-standard tools, the worktable of the CNC machine may be damaged. Sometimes in the CNC cutting process, the tool will hit the CNC table.

Next, how to set up the CNC router to avoid damage to the CNC wood router table?

We provide several convenient methods for your reference:

- Set the parameters of the CNC routermachine

When calculating the cutting path, do not set it according to the thickness of the material as before, but set it to: 0MM Before generating the G code file, the value of the “shovel lift distance” item must be: preset lift height and cutting The sum of the thickness of the material;

For example: when cutting acrylic, when the knife is placed on the surface of the material, the original height of the knife is 8mm, and the thickness of the material to be cut is 15mm, then the value time of “knife lift distance” is: 8 + 15 = 23MM; except for CNC router machine. In addition, the remaining operations have not been modified.

- Add anti-skid plates on the furniture CNC machine

For example, a furniture CNC machine with a vacuum suction cup can place a loose sheet on the table. The soft and breathable pine board itself will not affect the vacuum adsorption capacity, and can also prevent tool damage and office problems due to incorrect original settings.

- Milling table

Even if the furniture CNC machine is used on the table, even after the above treatment, accidental scratches will inevitably occur during long-term use. At this point, the counter should be polished again. When the bakelite or PVC of the workbench is too thin, you can cover it with a layer. In addition, it should be noted that when the furniture making machine leave the factory, in order to prevent the impact of logistics and transportation from damaging the table surface, after-sales personnel usually need to re-mill the machine.

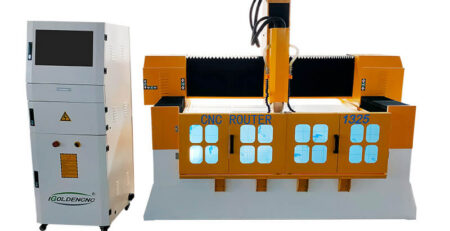

The CNC wood router table is mainly divided into T-slot aluminum table, CNC vacuum table and T-slot vacuum table.

For CNC machine with aluminum T-slot table, the parts must be fixed manually using jigs. For CNC vacuum table, you can put the workpiece directly on the table of CNC router. With the help of a vacuum pump, the CNC router will automatically and firmly absorb the workpiece. Relatively speaking, the CNC vacuum table can save a lot of time and make the adsorption firmer.

However, the vacuum table is not suitable for various CNC milling processes. The choice of a specific CNC router depends on the customer’s machining technology. Now, we will introduce to you these three CNC wood router table and their respective application ranges.

CNC machine are widely used in furniture industry, home decoration industry, wood industry, musical instrument industry and wood products. Choosing the right CNC wood machine will greatly improve production efficiency and improve production quality.

When choosing a CNC router, you need to choose a milling machine that suits your machining needs. It is not an advanced recording device that can increase the processing speed.

Leave a Reply

You must be logged in to post a comment.