Metal Laser Cutting Machine_Laser Cutting Machine Cabinet

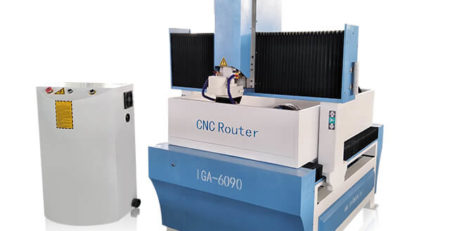

The application rate of metal filing cabinets in enterprises is very high. Generally, metal filing cabinets are welded from metal sheets, and the main process is welding and cutting. As a special metal laser cutting machine, the metal laser cutting machine can complete the cutting of metal materials at a precise speed, with fast cutting speed and high precision, which can greatly improve the cutting efficiency.

Metal laser cutting machine, cost-effective, single platform, simple structure, simple structure means sturdy and durable, because there is no complicated structure, basically no failure, easy maintenance after failure. Affordable, low operating costs and easy to maintain, metal laser cutters are ideal for thin sheet cutting.

Metal laser cutting machine, cost-effective, single platform, simple structure, simple structure means sturdy and durable, because there is no complicated structure, basically no failure, easy maintenance after failure. Affordable, low operating costs and easy to maintain, metal laser cutters are ideal for thin sheet cutting.

Although the metal laser cutting machine is low in price, there are many safety systems. It still comes with a full security system. It has the function of automatic alarm for abnormal working status of the equipment, and the operation page pushed by the control center is clear at a glance, which improves the elimination of equipment abnormality. rate and reduce maintenance costs.

Laser Cutting Machine

In the processing of metal filing cabinets, it is recommended to be equipped with a hand-held laser welding machine to manufacture finer metal filing cabinets.

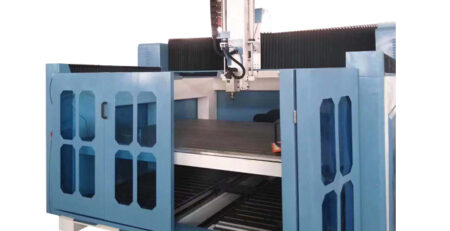

The square tube welding bed of metal laser cutting machine is welded by thick rectangular tubes with a diameter of 200*200mm. The bed can weigh up to 1 ton. The bed is annealed and milled through a large gantry to drill all the holes necessary for installation in one go. Drill all mounting holes precisely at once.

Higher tensile strength and dimensional stability. Effectively improve the accuracy of the bed and reduce the machining error of the workpiece. Increase the resistance and stability of the slide.

Reduce the wear and tear of equipment during use. The accuracy of the machine tool can be maintained for a long time, and it will not deform for 20 years. The equipment has good stability and reduces the machining error caused by the vibration of the bed.

Aviation aluminum profiles

High precision. The beam has good integrity, stiffness, toughness and ductility after artificial aging, solution treatment and finishing.

Aluminum alloy has the characteristics of light weight and strong rigidity, which is conducive to high-speed movement during processing, and high flexibility is conducive to high-speed cutting of various graphics on the basis of high precision.

efficient. The lighter beam can ensure the fast operation of the equipment, improve the processing efficiency, and ensure the processing quality at the same time.

Laser cutting machine cabinet

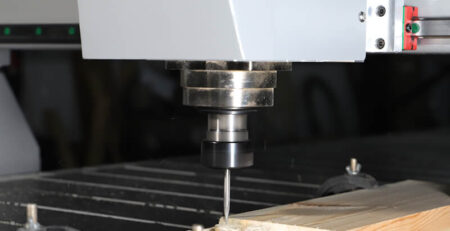

The laser head has a built-in motor drive unit, and the focusing lens is driven by a linear mechanism, which can automatically change its position within a range of 20mm. Users can set continuous focus through the program to complete the rapid perforation of thick plates and automatic cutting of plates of different thicknesses and materials. The compound lens group equipped with D28 integrates the light beam and optimizes the optical and water cooling design, so that the laser head can work stably for a long time.

Advantages of Laser Cutting Machines

Optimized optical configuration and smooth and efficient airflow design improve cutting effect;

The auto focus range is +10?-10mm, the adjustment accuracy is 0.01mm, and the adjustment speed is 100mmms;

The dust-proof design of the collimating protective mirror effectively protects the internal optical components;

Extend the distance between the protective lens and the nozzle, and increase the service life of the lens;

With drawer frame, it is more convenient and quick to replace the protective mirror.

The QBH connector is not limited and can be equipped with various lasers and QBH connectors.

Autofocus saves focus time and increases productivity by 10x.

By optimizing the structural design of the cutting head, the service life of the cutting head is extended.

Leave a Reply

You must be logged in to post a comment.