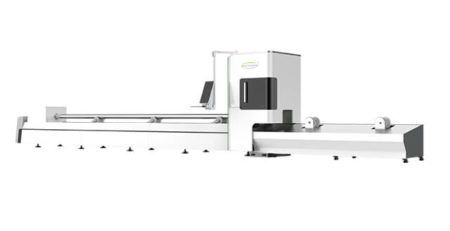

Metal Sheet Laser Cutting Machines

Laser cutting machines: a laser beam that will be fired from the laser generator, which is focused into a laser beam with high power density through the optical path system

The laser beam hits the surface of the workpiece so that the workpiece reaches the melting point or boiling point, while the high-pressure gas that is aligned with the beam will blow away the melt or vaporized metal.With the movement of the beam and the relative position of the workpiece, the material is finally cut and slit so as to achieve the purpose of cutting.Laser cutting is used to replace the traditional mechanical knife with invisible beams. It featured high precision, fast cutting, not limited to cutting pattern limitation, automatic typesetting saving material, smooth incision, low processing cost.

Tube laser cutting machine’s application area wider and wider and as the technology is more and more manual in China, so how to update the function more useful and easy to operate and control in the production cost, will be a question which you also interested in.

Advantages Of laser cutting machines

Co2 laser cutting machine is different from fiber laser cutting machine in many aspects, such as working principle of laser cutting machine, speed, maintenance, and other issues. The previous article describes the working principle of laser cutting machine and CO2 laser cutting machine and the difference of laser source to not repeat them here. The following will focus on the speed, cutting quality, and maintenance issues of both.

1. Fiber laser cutting machine has an extremely high cutting speed.

The fiber laser cutting machine’s cutting speed is twice that of the same power CO2 laser cutting machine and 4-5 times that of the YAG laser cutting machine. Therefore, the fiber laser cutting machine is very suitable for mass processing and production. The fiber laser cutting machine’s cutting speed is 10m/min.And the maximum positioning speed can reach 30m/min, which is far greater than the speed of wire cutting. Besides, the positioning accuracy of the fiber laser cutting machine is 0.05mm, and the repeat positioning accuracy is even as low as 0.02mm while meeting the needs of finishing. The following figure provides the cutting diagram of a 3000w fiber laser cutting machine for materials of different thicknesses for your reference.

3000w fiber cutting machine cutting speed

2. laser cutting machines has excellent cutting quality.

The fiber laser cutting machine has a small focus spot and large energy, coupled with the imported fiber laser cutting machine’s stable performance, which ensures higher work efficiency and better cutting quality. And the fiber laser cutting machine has high photoelectric conversion efficiency, strong, flexible light guiding effect, small structure, and simple operation.

3. The fiber laser cutting machine does not require post-maintenance.

The use cost and maintenance cost of fiber laser cutting machines are meager. The fiber laser cutting machine’s power consumption is only 20-30% of a similar CO2 laser cutting machine. Because the fiber laser cutting machine transmits energy through the optical fiber laser, it does not need a working gas and reflective lens, which greatly reduces the cost. Besides, the fiber laser cutting machine has the advantages of adjustment-free, maintenance-free, and high stability, which reduces the cost of accessories and maintenance time.

4. Fiber laser cutting machine has widely use.

Fiber laser cutting machines can be used in sheet metal processing, auto parts, household appliances, craft gifts, advertising, and decoration industries. It is suitable for cutting metal materials in various manufacturing and processing industries. Stainless steel, carbon steel, copper, silver, gold, and other metal plates and tubes can cut with fiber laser cutting machines. If you can’t judge whether the cutting material can be cut with a fiber laser cutting machine, please contact us for free.

The fiber laser cutting machine metal fiber laser cutting machine laser cutting machine enclosed is used in automobiles, agricultural machinery, textile machinery, engineering machinery, precision accessories, ships, metallurgical equipment, furniture, kitchenware, household appliances, Metal crafts, hardware tool processing, decoration engineering, advertising signs, sheet metal processing and other industries;

Applicable Materials:

laser cutting machines is suitable for variety of metal plates, stainless steel, carbon steel, galvanized sheet,pickling board, brass plate, aluminum plate, manganese steel, all kinds of alloy plates, rare metals etc.

Leave a Reply

You must be logged in to post a comment.