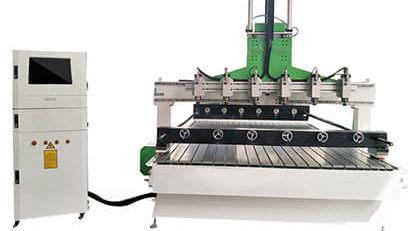

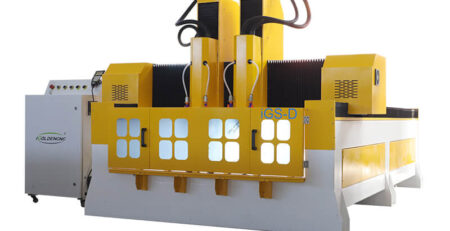

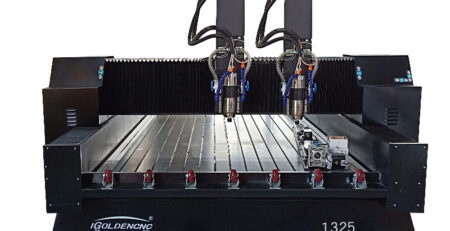

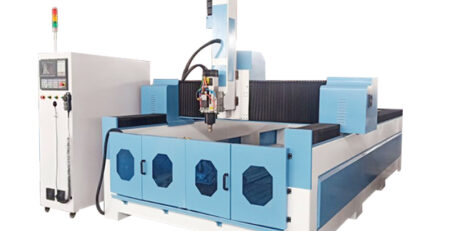

Six Sides Cnc Drilling Machine with Dual-spindles

What is the Six Sides Cnc Drilling Machine?

Six Sides Cnc Drilling Machine is a high-end CNC equipment for drilling and grooving of plate furniture production. Six-sided CNC drilling can complete six-sided processing, grooving and milling at one time. Easy to operate, flexible to use, free from manual intervention. The hinge hole can be processed in the linkage, and the thickness of the plate can be mirrored on both sides within a certain range.

What’s six side drilling machine?

Six-side drill machine is a numerically controlled drilling equipment used for the punching and slotting of plate parts in the production of panel furniture. The CNC six-side drill machine is a wireless code scanning gun.

Scanning the hole and slot information of the plate type, positioning once to realize the processing of the four sides and front and back of the plate and the front and back slot processing of the plate, with high processing efficiency and fast speed, is currently a high-end custom furniture manufacturer Essential NC hole drilling equipment.

How to use six side drill machine ?

It is usually realized by the CAM software supporting the six-side drilling system. It is necessary to understand the functions of the CAM software.

First of all, we need to figure out the working principle of full-automatic cnc cutting machine + cnc six-side drilling + design and disassembly software.

How much six side drilling machine?

Our factory has 10 years of R & D, production, and training technical experience. 60% is sold abroad, so the product positioning is also very high.

We use imported systems and first-line brand hardware to assemble. We have time to invite you to visit the site to learn more about the configuration system and its own detailed assembly structure.

Advantage

- Complete six sides processing and slotting and milling at one time; Easy to operate, flexible to use, and free from manual intervention.

- Equipped with a rear feed roller, so the processing plate supports two directions (front and rear) to come out. As for rear direction, an optional power expenditure roller or a side roller can be selected.

- Equipped with front, rear, left, right and horizontal hole machining auxiliary pressure rollers; With alll-round auxiliary pressure processing to ensure the accuracy of horizontal hole machining during workpiece processing.

- Designed with vertical pressure roller to ensure the machining accuracy of vertical hole and slotting.

- Manufactured with upper and lower spindles, so there is no need to turn the plate for forward and reverse slotting.

Leave a Reply

You must be logged in to post a comment.