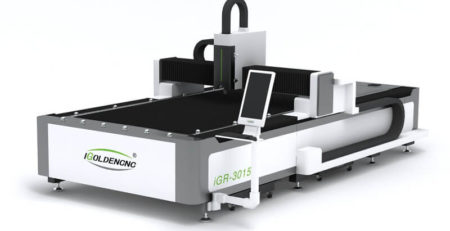

Stainless Steel Laser Cutting Machine Manufacturer

Laser Cutting Machine Manufacturer

Shandong IGOLDEN CNC Technology Co., Ltd, is a comprehensive corporation integrating laser & CNC technology research and development, equipment manufacturing, sales and after-sales, intelligent medical furniture production, foreign trade import and export, park management services and e-commerce. The Group’s brands include IGOLDENCNC, IGOLDENLASER, ZIGUICNC, ZIGUILASER, INEWLASER, IGOLDENOF, etc., products cover many fields such as intelligent medical furniture, industrial laser machine, CNC router machine, panel furniture production line, solid wood furniture production line, plasma cutting equipment and supporting application equipment. Group now has more than 500 employees at domestic and abroad, has enjoyed more than 10 independent brands, and has built a sound sales channel and service network worldwide relying on e-commerce and digital marketing.

What do you need to know about laser tube cutting machine?

Laser tube cutters are very fast and accurate computer controlled cutters that oàer numerous beneÕts to a variety of manufacturers for cutting metal plates, sheets and pipes. In many cases, they are your best bet. Cutting pipe to achieve the power to cut to the bottom, and the length of accurate, no coke edge.

Laser tube cutting machine can solve the problem of tube cutting very well.

Why should you consider using a tube fiber laser cutter?

1 No pressure, workpiece does not deform

Cutting with laser cutting equipment is not affected by material hardness. This is determined by the characteristics of the laser. This is a lot of advantages over traditional equipment. Laser cutting can perform deformation on steel plate, stainless steel, aluminum alloy and hard plate.

2 No secondary processing, high processing efficiency

Stainless steel sheets are processed by fiber laser engraving machine, and non-contact treatment methods do not affect the deformation of the workpiece or the progress of the next process. After the laser is cut, no secondary treatment is required, and the cutting surface is smooth.

3 High positioning accuracy, smooth cutting surface

The laser beam is focused into the dot, making the focus to reach the high power density. The material was rapidly heated to the degree of evaporation and evaporated. It has high beam quality, high positioning accuracy, and high cutting accuracy.

4 No tool wear, low maintenance cost

The use of laser cutting machine is cut with stainless steel without material loss, which has a high cutting light conversion rate, also has low processing costs, and uses fiber laser cutting machines without maintenance.

In addition to traditional cutting, corner cutting, opening, and trimming unparalleled flexibility and processing precision, laser cutting machines can also achieve large-scale production of customization and personalization. Since the laser cutting machine uses “non-contact processing”, there is no need for mold production and cost. Processing graphics is generated by software, mode is diverse. Therefore, it can effectively improve product quality, reduce production costs, and meet the customization and improvement of enterprise production needs.

What kind of manufacturing work makes a laser tube cutter meet its limits?

While laser cutters can provide a fast, versatile and accurate way to cut pipes, plates and plates, there are some limitations:

1. Laser tube cutter is usually used for cutting without bevel. As a result, many laser cutting machines either do not have the cutting ability, or the ability is not the main focus.

2. Laser tube cutters are very expensive and the investment is high enough that a single production shift is not enough to allow manufacturers to achieve a quick return on investment (ROI).

3. Laser tube cutters are becoming more and more common, and there are more and more workshops with laser cutters in any given manufacturing Õeld. As a result, the market has become more competitive, leading to lower outsourcing costs and making the return on any purchased investment more diÞcult to repay.

4. The cost of laser tube cutting machine is relatively high for the following reasons:

5. The cost of buying laser cutting machines is high. Higher energy consumption. Higher operating costs. Although the productivity of thinner materials can be very high, laser cutting eÞciency decreases as the material thickness increases. Laser tube cutters often require people with higher technology and expertise to perform often more complex maintenance tasks.

The following factors determine which laser cutting machine model you think in IGOLDEN:

1.Cutting purpose

You must consider, what kind of materials do you want to cut, board, tube or board + pipe cut in a machine?

2. Material specifications

What do you want to cut, how much is the size of the raw material? thickness?

3. Factory space

How much space is your factory situation and how many spaces you have kept for laser cutters?

4. Think about the present and future

What is the current business you are doing, what is the future plan? Thinking about it.

5. Work efficiency

What is the efficiency of a laser cutting machine?

6. New business opportunities

If you are willing to extend the laser cutting business to a larger scale, please choose a larger machine power supply?

7. Process after laser cutting

Do you consider laser cutting processes? bending? welding? clean? These Seenfeng can support.

8. Budget plan

This is just thinking about yourself. How much do you want to invest in laser cutting business, what do you expect to earn a cost?

Leave a Reply

You must be logged in to post a comment.