Automatic edge banding machine factory direct sale

How much is a fully automatic edge banding machine, the top ten famous brands of automatic edge banding machine, automatic edge banding machine, automatic edge banding machine manufacturers, automatic edge banding machine, edge banding machine

When we buy wardrobes, we can’t see much difference from the surface, but the price is very different. In fact, in addition to different brands of wardrobes and different materials, the processing technology is also different. Next, let me talk about how to judge the quality of the wardrobe from the problem of the edge sealing of the wardrobe. Professional large enterprises use automatic edge banding machines to complete a series of processes such as edge banding, trimming, chamfering, polishing and so on at one time. The glue is evenly applied and the pressure is stable, the sealing line is straight, and the edge banding is smooth and delicate. it is good. And those small manufacturers use semi-automatic edge banding machines; even gluing and pressing the edges by hand, and then trimming and polishing with wallpaper knives and sandpaper. Due to the unevenness of manual gluing, the seal will also have the problem of opening and falling off. So friends, don’t pay too much attention to the price when buying wardrobes. Don’t bring a series of troubles to our later use because of the price problem at that time. When buying wardrobes, you should choose the ones produced by large enterprises.

When we buy wardrobes, we can’t see much difference from the surface, but the price is very different. In fact, in addition to different brands of wardrobes and different materials, the processing technology is also different. Next, let me talk about how to judge the quality of the wardrobe from the problem of the edge sealing of the wardrobe. Professional large enterprises use automatic edge banding machines to complete a series of processes such as edge banding, trimming, chamfering, polishing and so on at one time. The glue is evenly applied and the pressure is stable, the sealing line is straight, and the edge banding is smooth and delicate. it is good. And those small manufacturers use semi-automatic edge banding machines; even gluing and pressing the edges by hand, and then trimming and polishing with wallpaper knives and sandpaper. Due to the unevenness of manual gluing, the seal will also have the problem of opening and falling off. So friends, don’t pay too much attention to the price when buying wardrobes. Don’t bring a series of troubles to our later use because of the price problem at that time. When buying wardrobes, you should choose the ones produced by large enterprises.

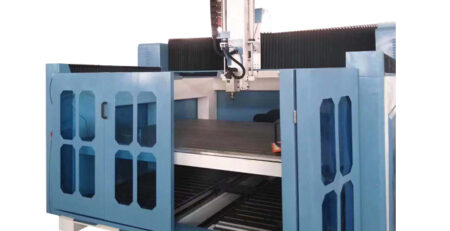

The automatic edge banding machine is mainly composed of a body, a pressure beam device, a conveyor belt transmission device, a rear support device, an edge banding installation, adjustment and automatic cutting device, a melt coating device, an edge banding and pressing device, etc., and a polishing device. , electrical control devices, pneumatic control devices, etc.

The automatic edge banding machine manufacturer will tell you what the purpose of the automatic edge banding machine is?

This machine is mainly used for straight edge sealing of plywood, fiberboard, particleboard and other sections. The structure is compact, the layout is reasonable, and the appearance is beautiful; it adopts sound insulation, dust accumulation, anti-overload and other devices; it has working units such as front and rear automatic cutting, upper and lower automatic trimming, and surface polishing. It is a new, multi-functional, semi-automatic edge banding machine. Favored by woodworking and furniture factories.

The automatic edge banding machine can be transported by a forklift through the bottom of the fuselage. Use two round rods to pass through the holes on each side of the bottom of the fuselage. During transportation, pay attention to the balance of the weight of the whole machine and protect the appearance of the paint. To store the machine, place the machine in a dry environment in the greenhouse, covered and sealed with a plastic bag.

The edge banding machine is suitable for straight edge trimming and trimming of medium density fiberboard, block board, solid wood board, particle board, polymer door panel, plywood, etc. , flushing, chamfering, rough repairing, fine repairing, scraping and polishing, etc., the edge sealing is fine, smooth, and feels good, and the sealing line is straight and smooth.

It mainly includes the fuselage, each processing department, and the control system. The main processing components are: pre-milling, gluing, edge banding, flushing, rough trimming, fine trimming, profiling tracking, edge scraping, polishing, grooving. Mainly used for panel edge sealing of panel furniture. It is characterized by automation, high efficiency, high precision and aesthetics. It has been widely used in domestic panel furniture manufacturers.

The edge banding machine is stable, reliable and durable, and the price is moderate. It is especially suitable for manufacturers of large and medium-sized furniture, cabinets and other panel furniture. The equipment has the functions of pre-milling, gluing and sealing, flushing, finishing, scraping, polishing, grooving, etc.:

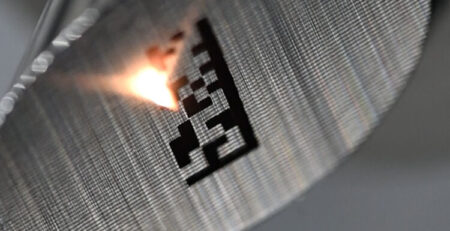

- Pre-milling: Double milling cutters are used to modify the ripple marks, burrs or non-perpendicular phenomena caused by panel sawing and slicing sawing to achieve better edge sealing effect. It makes the bonding between the edge band and the board more closely, and the integrity and aesthetics are better.

- Glue and seal the edge: through the special structure, the edge-sealing plate and the edge-sealing material are evenly coated on both sides, so as to ensure stronger adhesion.

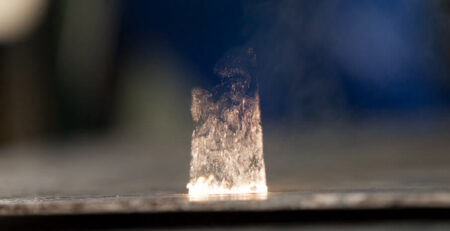

- Straight head: through the precise linear guide motion, the automatic tracking of the mold and the fast cutting structure of the high-frequency high-speed motor are adopted to ensure that the cut surface is smooth and smooth.

- Refining: All of them adopt the automatic tracking of the mold and the high-frequency high-speed motor structure to ensure the smoothness of the upper and lower parts of the trimmed plate. It is used to repair the excess edge banding material above and below the edge banding strip of the processed sheet.

- Scraping: It is used to eliminate the ripple marks caused by the cutting process of non-linear motion of trimming, and make the upper and lower parts of the plate more smooth and tidy.

- Polishing: Use a cotton polishing wheel to clean the processed plate, and make the edge-sealing end surface smoother by polishing.

- Slotting: It is used for direct slotting of wardrobe side panels, bottom plates, etc., which is more convenient and quick to reduce the process of panel sawing; it can also be used for slotting aluminum edging of door panels.

Leave a Reply

You must be logged in to post a comment.