How To Choose Between Plasma Cutting Machine and Laser CNC Machine

When to choose plasma cutting machine

In any of the following situations, I usually recommend that you choose a plasma cutting machine:

- The shape of the parts you need to cut is very simple, without many complicated cuts and gaps;

- You need to cut metal plates of medium or large thickness (for example, 25mm or more);

- There are no very strict requirements on the quality of grooving and cutting surface;

- Need to cut a large amount of metal with high reflectivity, or need to cut this material for a long time.

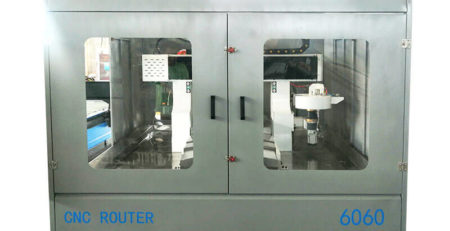

iGOLDEN multifunction plasma cutting machine

The working size of this plasma machine is 1300*2500mm(can option 1500*3000mm/ 2000*3000mm). Using Hypertherm 125A plasma power supply, the plasma torch can work stably to ensure smooth cutting process. Plasma cutting machine is suitable for cutting low carbon steel, iron plate, aluminum plate, copper and other metal materials, and it is widely used.

When to choose laser CNC machine

However, if any of the following conditions are met, it is usually recommended that you choose a laser CNC machine:

- Need tighter tolerance specifications, precise cutting and/or small opening parts;

- To cut metal plates less than 6mm quickly;

- In addition to metal, other non-metal materials must be cut, such as wood, PVC, acrylic, rubber, etc.

- In addition to cutting, you also want to engrave designs on the workpiece;

- There are higher requirements for precision cutting, notch, cutter head quality and surface.

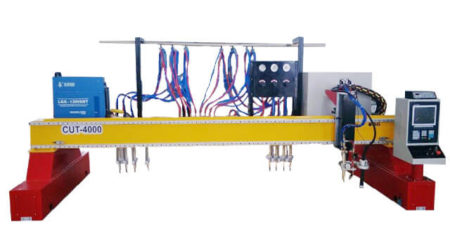

Metal Fiber Laser Cutting Machine

This is our latest fiber laser cutting machine for cutting metal materials. It uses a sturdy, durable tubular welding bed. The laser CNC machine adopts imported fiber laser generator, which has stable operation and long service life. Very suitable for cutting metal plates with a thickness of less than 3mm.

The above comparison table lists the main performance differences between CNC plasma cutting machine and laser CNC machine. Hope this table can help you choose the die cutting machine suitable for your application.

In short, the type of material, thickness and your requirements for cutting results determine the choice of laser CNC machine or plasma cutter. Both machines have a wide range of fast and efficient applications. But it may be more suitable for specific projects. Another thing to remember is that laser cutting machine and plasma cutting machine may produce slag, gas, smoke or strong light during the cutting process. Therefore, be sure to take appropriate safety protection measures.

Leave a Reply

You must be logged in to post a comment.