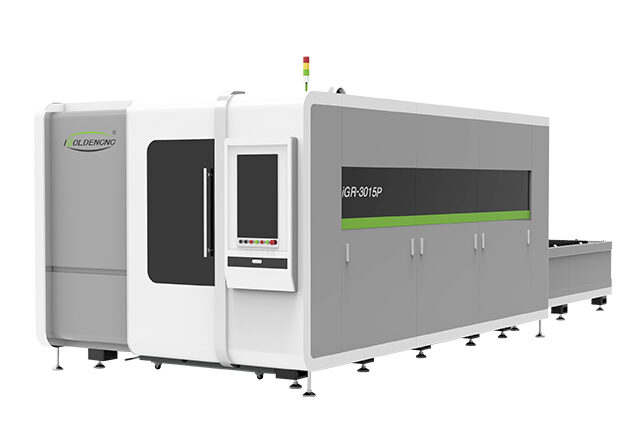

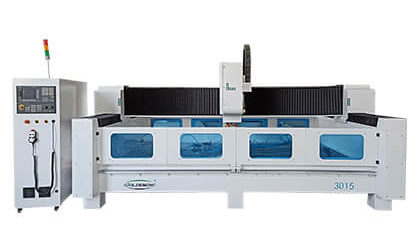

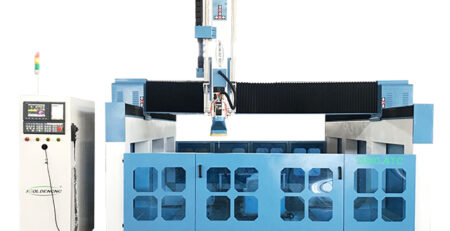

Enclosure fiber laser cutting machine_Metal laser cutting machine

The enclosed fiber laser cutting machine adopts a fully enclosed laser protective cover, is equipped with a special laser protective glass observation window, and is equipped with a scientific smoke and dust recovery and purification treatment system, which is overall beautiful, safe and environmentally friendly. The material is convenient and the processing efficiency is high; it is a mid-to-high-end special equipment for laser cutting of sheet metal, and it is a must-have product for modern manufacturing enterprises.

Laser cutting is the best cutting method among the various cutting technologies that people have mastered today. The advantages of laser cutting are: small thermal deformation, high cutting accuracy, low noise, no pollution, easy to achieve automatic cutting, although the initial investment is large (disadvantage). ), but the machining cost is 50% less than machining. As an advanced manufacturing technology, laser cutting has the advantages of wide application range, flexible process, high processing accuracy, good quality, clean production process, and easy to realize automation, flexibility, intelligence, and improve product quality and labor productivity.

Fiber lasers are a hot spot in the laser field in recent years, and fiber lasers have a tendency to rapidly replace traditional YAG and C02 lasers in the processing field. It is widely believed that medium power fiber lasers will be the third generation of state-of-the-art industrial processing lasers. Fiber lasers have many unique advantages: good beam quality; small size, light weight, maintenance-free; air-cooled simple and easy-to-operate parts; low operating cost and can be used in industrial environments; long life, high processing accuracy, and high speed; electrical energy The conversion efficiency is high, and intelligent, automated, and flexible operations can be realized. From the perspective of the development of the entire laser technology, fiber laser represents the development direction and trend of laser, and it has important application prospects in the fields of industry and national defense.

Fiber lasers are a hot spot in the laser field in recent years, and fiber lasers have a tendency to rapidly replace traditional YAG and C02 lasers in the processing field. It is widely believed that medium power fiber lasers will be the third generation of state-of-the-art industrial processing lasers. Fiber lasers have many unique advantages: good beam quality; small size, light weight, maintenance-free; air-cooled simple and easy-to-operate parts; low operating cost and can be used in industrial environments; long life, high processing accuracy, and high speed; electrical energy The conversion efficiency is high, and intelligent, automated, and flexible operations can be realized. From the perspective of the development of the entire laser technology, fiber laser represents the development direction and trend of laser, and it has important application prospects in the fields of industry and national defense.

Technical features of large encirclement fiber laser cutting machine:

- The machine tool adopts a high-strength integral welding bed, and the high-temperature return of gold eliminates stress and is not easy to deform;

- Imported high-precision ball screw/rack and pinion drive, high-precision linear guide;

- Driven by imported servo motor, equipped with imported high-rigidity precision reducer;

- The machine tool is equipped with an automatic lubrication device, and the cutting area is equipped with a dust removal and smoke exhaust device;

- Laser modular structure, high performance and maintenance-free;

- The software of turning bad karma cutting is simple, convenient and flexible, and can freely design cutting of various graphics and characters.

- Our high-power laser cutting machine adopts gantry type single-side double-drive structure, imported high-precision reducer, rack and pinion and linear guide rails, with stable transmission, fast acceleration and high positioning accuracy.

- The automatic zoom cutting head is adopted, and the cutting focus position can be changed by setting the position of the system parameters, which abandons the traditional manual adjustment.

- Equipped with lens monitoring function, it can automatically identify whether the lens temperature is normal, and ensure the stability of product processing.

- One-key calibration, automatic edge finding, automatic typesetting, leapfrog and other powerful craft functions make the operation easier.

Leave a Reply

You must be logged in to post a comment.