Best ATC Woodworking CNC Router Machine

High cost performance. Processing requirements can be met without high procurement and training costs. This type of wood engraving machine can help users save 30% purchase cost. It also can be used as CNC wood cutting machine, especially for MDF, wood panel cutting.

Best ATC CNC Router Wood

ATC stands for Automatic Tool Change, which means that the machine can change cutting tools automatically based on the requirements of the design being cut.The ATC Woodworking CNC Router Machine is typically equipped with a spindle motor, a cutting table, a control panel, and various cutting tools. The spindle motor is the power source that drives the cutting tool and can be adjusted to control the speed and torque of the cutting process. The cutting table provides a stable platform for the material being cut and can be adjusted to accommodate different sizes and shapes of workpieces.

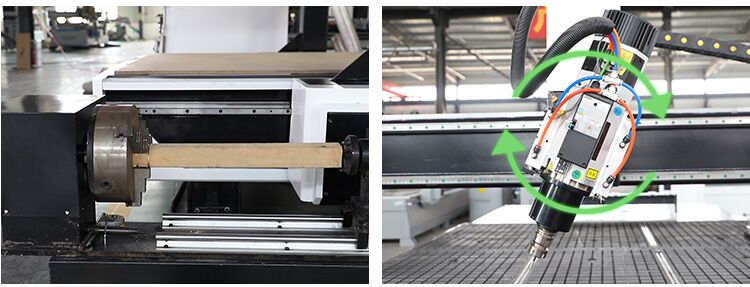

Tool changer magazine + 9KW air-cooled spindle

Rotary device + Swing head

How does a ATC CNC Wood Router Help a Manufacturer?

1. Improved Production Range

Industrial ATC CNC wood routers have revolutionized the woodworking industry. This computer-controlled machine rarely produces any waste pieces and operates at high-efficiency. This machine can substantially increase the range of production of woodworking firms without requiring it to hire a qualified technician for the machine.

2. Larger Cutting Field

Be it large pieces like stair risers or small 3d carving, a CNC Router for Wood Carving is capable of producing designs that are a challenge for a standard wood router that too at a higher speed. In the case of mass production, a woodworking firm can opt for bigger CNC wood router that have a low margin of error and produce large pieces of wood at ease.

3. Ease of Operation

Standard routing requires a woodworker to physically manipulate the wood router. This method is not advisable as it severely impacts the quality of the product and safety of the woodworker. Besides, the working of these hand routers is something that cannot be taken for granted, hence, it requires an operator with significant experience along with the training of the router.

Whereas, a CNC wood router does not require a skilled operator. It only requires a woodworker to have computer training in coding, which is could be gained in a matter of a few months.

4. Less Waste, Less Dangerous

This is a common issue among the woodworkers using standard wood routers. Their investment is significantly higher than their compatriots who are using CNC Routers for Wood. The reason being, the loss of money is directly related to the loss of material on the work floor. So, more the waste, the cost incurred is also more. Lacking in accuracy, hand routers tend to provider results on the expensive side of the spectrum. Furthermore, the chances of woodworker making a serious error are also high.

5. Flawlessly Accurate

As mentioned above, the best part about the CNC wood router is that it is accurate. Since it is a computer-controlled machine, the CNC router possesses the capacity of producing thousands and hundreds of finished products that too at the same time! For firms and woodworkers who value time, accuracy, and high-quality, this machine is the insurance for making your work invaluable.

CNC Wood Router Maintenance

Proper maintenance and operation in the right way can extend your CNC wood machine’s life and reduce the incidence of failures.

Avoid direct sunlight, excessive humidity, and dust

Keep your wood CNC machine away from any equipment with high vibration

Keep dust away from wood CNC router machine wheels and bearings

Use CNC wood carving machine according to manufacturer’s wood CNC machine instructions

Leave a Reply

You must be logged in to post a comment.