Operation method and steps of stone engraving machine

How much is the price of a stone engraving machine, the operation methods and steps of the stone engraving machine, which brand of stone engraving machine is of good quality, the video of the operation tutorial process of the stone engraving machine, the top ten brands of stone engraving machine

With the development of the industrial engraving industry, everyone has higher requirements for stone engraving products. Therefore, the functions of stone engraving machine equipment are also increasingly perfect to cope with the changing market. So what are the characteristics and functions of the stone engraving machine? What fields are it used in?

With the development of the industrial engraving industry, everyone has higher requirements for stone engraving products. Therefore, the functions of stone engraving machine equipment are also increasingly perfect to cope with the changing market. So what are the characteristics and functions of the stone engraving machine? What fields are it used in?

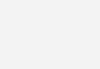

Features of stone engraving machine:

It adopts imported 30 linear square rail, double row and four rows of ball sliders, with large bearing capacity and stable operation.

The high-power spindle has long service life, stable operation, good starting performance and large torque.

Using the numerical control operating system, the operation is simpler, the design is more humanized, and the unique intelligent budget rule is adopted to give full play to the potential of the motor, realize high-speed processing, curve and line synchronization, and curve more.

Using imported high-power servo motor drive system, the machine runs fast and has strong power.

The dust cover is designed to prevent dust and dirt, ensure the normal operation of the machine, and make the machine life longer.

Split structure bed, seamless welding of thick-walled square tubes, and vibration aging treatment, durable, not easy to deform, to ensure high stability in machining engineering.

The high-power, high-torque air-cooled or water-cooled electric spindle is adopted, and the drive system adopts Japan Yaskawa.

The X, Y, and Z axes of the equipment all use Taiwan’s self-lubricating square scraping type linear guides, which have large load-bearing redundancy and long service life. For high-level CNC equipment, the square linear guide has three times longer life and higher precision than round rails.

Imported four rows of steel balls, widened linear guides, self-lubricating blocks, equal force in all directions during engraving, ensuring mechanical precision and strength.

Intelligent processing out-of-bounds protection to prevent the mechanical collision caused by the design layout exceeding the processing width.

Diversified control can control the processing speed, idle speed and knife drop speed respectively, which greatly improves the quality and processing efficiency of processed products.

The system is suitable for mold making, cutting, routing, drilling, engraving, etc. Offline operation is possible.

Stone engraving machine applicable industry

It can be widely used in the production of lost casting foam molds, cast iron molds, foam molds, car wood molds, train wood molds, aviation wood molds, ship wood molds, paraffin molds, etc.

Whether buying a stone engraving machine or using it for product engraving, we need to understand its functions and features so that we can operate it better. Choose the right stone engraving machine product according to your industry.

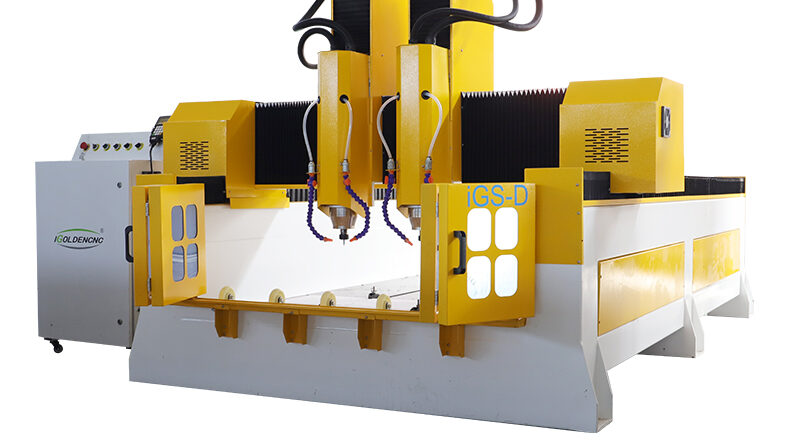

Features of stone engraving machine:

The breakpoint memory method is adopted to ensure that it can be processed in the event of an accident (broken tool) or shift change.

Unique way of saving multiple workpiece machining origins

Reinforced table, durable, long-term use without deformation, so that the positioning accuracy is more accurate.

The engraving is fine and free of serrations, and the bottom surface is flat and smooth with clear outlines.

Precision welded high frequency aging bed.

Application range of stone engraving machine: one machine can complete plane engraving and three-dimensional engraving.

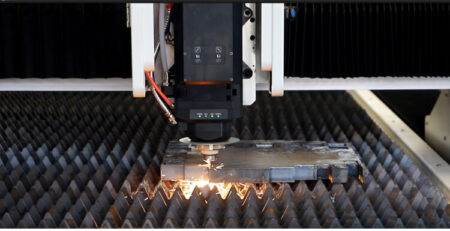

Three-dimensional carving: stone lions, Buddha statues, figures, handicrafts, musical instruments processing, pen holder carving, wood products, furniture accessories, sofa legs, stair columns, handrails 360-degree carving, rotating shaft carving, three-dimensional processing, etc.

Plane engraving: It can be used for engraving and embossing of text and patterns on engineering signs, large-scale reliefs, home decoration backgrounds, railings, murals, marble, granite, tombstones, milestones, tiles, etc.

The stone engraving machine can also engrave and paint on the tiles, and engrave abstract patterns to meet the needs of personalized home decoration and art design. The engraving machine machinery has been exported to more than 20 countries and regions in Europe, America, Southeast Asia, etc., and enjoys a good reputation in the domestic stone processing industry! Welcome new and old customers from all over the country to visit our company.

Leave a Reply

You must be logged in to post a comment.