What Are The Common Engraving Methods Of CNC Stone Engraving Machine For Stone?

For each different stone and the different needs of each customer, stone carving also has different carving processes according to different products, so what are the common carving methods of stone carving machines, let’s take a look.

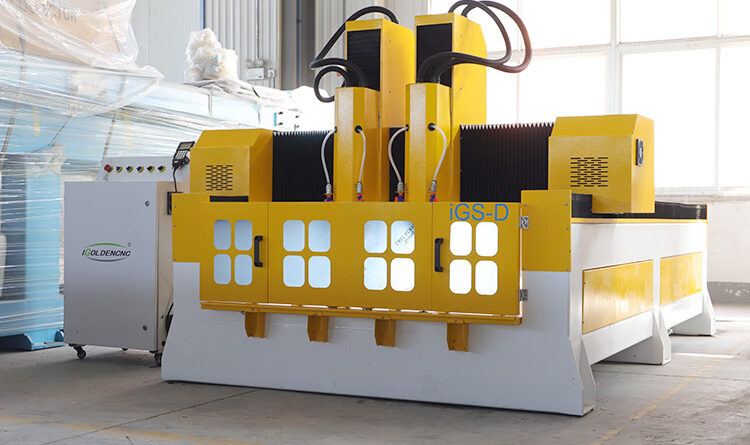

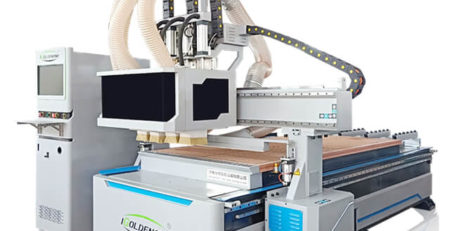

CNC Stone Engraving Machine For Stone

CNC Stone Engraving Machine For Stone

- Flat carving: Flat carving is basically carving on stone, that is, carving out the image and concave the picture. Flat carving is basically painting on flat media (such as slate, tiles), and there is basically no real carving, so it is also called “Symphony”.

For flat engraving, the engraved pattern must maintain a certain height and depth with the engraved surface. There are two types of flat carving: negative carving and positive carving: part of the pattern is dug out so that the displayed pattern is lower than the ground. This method is called negative carving. For example, the ring line of the core board of the cabinet door, the skirt board, the water cover teeth on the screen socket, etc., mostly use the flat carving process, and mostly use the positive pattern. The inscription technique is not used much on furniture.

- Relief: Relief is two-dimensional, the image is preserved, the rest is eliminated, and the picture stands out on the object.

Relief is a form of engraving in which the sculptor engraves the image he wants to create on a flat plate, separating it from the plane of the original material. Relief is the product of the combination of sculpture and painting. It uses compression to deal with objects, relies on factors such as perspective to represent three-dimensional space, and can only be viewed from one or both sides. Reliefs are generally attached to another plane, so they are used more in architecture and can often be seen on utensils. Due to its compact nature, it takes up little space, making it suitable for decoration in various environments.

Relief is a figure-shaped relief formed on the stone surface (as opposed to sinking sculpture), which is a semi-stereoscopic sculpture. According to the depth of image modeling, it can be divided into bas-relief and high-relief. Bas-relief is a single-layer statue with a relatively simple content; high-relief is a multi-layer statue with a more complex content. The carving technique and expression style of relief sculpture are basically the same as that of round sculpture. Ancient and modern Chinese and foreign, many large-scale monumental buildings, high-end mansions, residential houses have such decorations. The main works are wall block, dirty window, dragon column (early) and column foundation.

- Round carving: round carving, also known as three-dimensional carving, is the overall expression of art on carvings. The observer can see all aspects of the object from different angles. It requires the engraver to carve in all directions from front, back, left, right, top, middle and bottom. Circular sculpture, also known as three-dimensional sculpture, refers to a non-compressed three-dimensional sculpture that can be appreciated from multiple directions and angles.

The techniques and forms of round carving are also varied, including realism and decoration, figurative and abstract, indoor and outdoor, shelf and large-scale urban sculpture, colored and colorless, etc. Sculpture content The subject matter is also colorful, which can be figures, animals, or even still life’s; materials are more colorful, including stone, wood, metal, clay sculpture, plaster, textiles, paper, plants, rubber, etc. Mostly used in fountains or gardens and indoors.

- Shadow carving: shadow carving, as the name suggests, its sculpture image is lifelike, just like photography. It is an innovative new process developed on the basis of the earlier “needle black and white” process. On a brightly polished bluestone slab only 1.5 cm thick, various micro-steel drills of different thicknesses are used according to the size of the lead point. An organic combination of depth, thickness, density and realism, carefully crafted to correspond to imaging.

Granite Engraving Machine Features:

The CNC Stone Engraving Machine For Stone bed is welded by the thick wall steel seamless tube, high temperature tempering treatment, high rigidity, bearing strength better .

Dual stepper motor drive for Y-axis, moving stably.

DSP control with good software compatibility, suitable for Type3, Artcam, Castmate, Ucanam.

Constant spindle motor 5.5 KW power, strong cutting strength, high efficiency.

High precision rack transmission, high speed.

Imported linear square guide way, double row four row slider, high precision, long life time.

Well selected electrical accessory, let the failure rate to the minimum.

With water and automatic water supply and cooling system.

Comment (1)

For each different stone and the different needs of each customer, stone carving also has different carving processes according to different products, so what are the common carving methods of stone carving machines, let’s take a look.