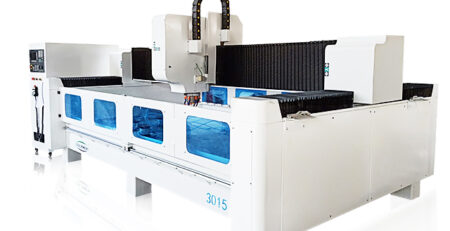

Focal Length Of 20mm Metal Laser Cutting Machine?

When the fiber laser cutting machine is engaged in the cutting operation, there will be some differences in the cutting quality with different focus positions.

20mm Metal Laser Cutting Machine

Therefore, in order to further improve the cutting quality of the laser cutting machine, it is very important to adjust the focus position of the 20mm metal laser cutting machine.

The adjustment of the focal position of the fiber laser cutting machines to optimize the cutting quality is determined from the situation where the cutting focus is on the cutting material:

Three kinds of 20mm metal laser cutting machine focal length

When the focus of the fiber laser cutting machine is in the best position, the slit is minimum and the efficiency is highest to obtain the best cutting results. The following are the focal lengths of three fiber laser cutting machines.

Negative focal length

Negative focal length (the cutting focus is on the cutting material) is mainly used when cutting thick metal plates. Negative focal length cutting thick plate needs large cutting amplitude, lead to the nozzle to transport insufficient oxygen and make the cutting temperature drop, the cutting surface is relatively rough, not suitable for high precision precision cutting.

The negative focal length

Internal negative focal length (the cutting focus is located inside the cutting material) is usually applied to fiber laser cutting machines in cutting materials such as aluminum, aluminum alloy and stainless steel. According to the focus principle of cutting surface, the relative cutting point on the workpiece surface is large, and in this mode, the use of 20mm metal laser cutting machine to cut the airflow is large, the temperature is high, the cutting perforation time is slightly longer. So this kind of cutting is mainly used in cutting aluminum or stainless steel and other materials with high hardness

0 the focal length

0 focal length (the cutting focus is on the surface of the cutting material) is usually used when cutting SS41, SPH, SPC and other materials. 0 focal length cutting focus is close to the workpiece surface, due to the cutting surface of the upper and lower smoothness is not the same, so when cutting the upper surface of the cutting is relatively smooth, and the lower surface is relatively rough. This way of cutting focus positioning needs to be based on the actual situation of the upper and lower surface process requirements.

It is very important to determine the focus position of the fiber laser cutting machine according to the actual situation. A reasonable focus position can make the fiber laser cutting machine work more reasonably.

20mm metal laser cutting machine focus position: focus on the workpiece surface

The upper and lower surface smoothness of the workpiece in this mode is not the same. Generally speaking, the cutting surface close to the focal point is relatively smooth, while the lower surface far from the focal point is rough. This mode should be based on the actual application of the upper and lower surface of the process requirements.

Fiber laser cutting machine focus position: focus in the workpiece

This method is also called normal focal length. When you need to cut the workpiece for stainless steel, aluminum steel plate often use the cutting point in the workpiece mode. But a disadvantage of this way is that, because the focus is far away from the cutting surface, the relative cutting amplitude is larger than the cutting point on the workpiece surface, and the cutting airflow required in this mode is larger, the temperature is sufficient, and the cutting and perforation time is a little longer. So when you choose the material of the workpiece is mainly stainless steel or aluminum and other materials with large hardness.

Fiber laser cutting is a hot cutting method that uses the focused high power density laser beam as the main heat source. The laser beam ensures that where the workpiece is hit by the beam, the material quickly melts and evaporates. At the same time, molten material is blown away with the help of a fast air flow. By doing this continuously, the workpiece is cut

If you are looking for more information concerning fiber laser cutting machines or are interested in finding a professional fiber laser cutting machine manufacturer to buy wonderful types of them. Then, you have turned on the right passage, please make sure you check out the web of IGOLDENCNC this professional laser machine manufacturer will definitely satisfy any orders and needs of you with their reliable and professional knowledge and their amazing production speed.Thank you for reading

Leave a Reply

You must be logged in to post a comment.