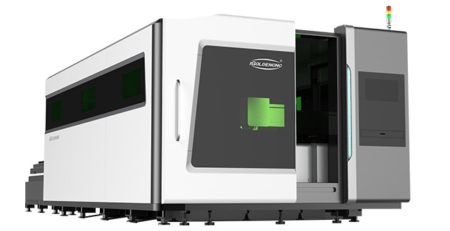

Tube laser cutting machine, laser cutting tube

Laser cutting has a very wide range of applications in current use, especially in the cutting of concrete pipes. The traditional pipe cutting mainly adopts drum cutting and sawing machine, but these processing methods have great problems. For example, if the efficiency is low and the labor intensity of workers is relatively high, the accuracy of the laser cutting machine cannot meet the requirements, while the laser cutting can have the advantages of faster work efficiency, better processing effect and so on.

In the current cutting industry, laser cutting machines can be widely used in aviation, construction machinery, automobile manufacturing, etc.

There are many inconveniences in the transportation and processing of laser-cut pipes. Although the traditional cutting method can meet some requirements within a certain range, the processing efficiency is low, and the processing method is relatively poor. Therefore, the choice of new laser cutting has broad development and prospects in tube processing.

Laser cutting pipes have high incision, small heat affected zone, fast cutting speed, good flexibility, and smooth incision. There are many advantages and points in the machining process, such as no wear. With the emergence of CNC laser cutting machines, there are more and higher requirements for free-form surfaces and curved surfaces in space.

Laser cutting pipes have high incision, small heat affected zone, fast cutting speed, good flexibility, and smooth incision. There are many advantages and points in the machining process, such as no wear. With the emergence of CNC laser cutting machines, there are more and higher requirements for free-form surfaces and curved surfaces in space.

At present, the width of the laser cutting machine on the market is , the heat-affected zone is relatively small, the cutting is smooth and clean, and there is no impact. Compared with traditional processing methods, the cutting efficiency can be increased by 8-20 times, the processing speed can be increased by 20%, the processing cost can be greatly reduced, and the impact on the environment is relatively small.

Laser cutting is a non-contact cutting method that is very necessary in the entire future market. There is no pressure, collapse or deformation of the pipe wall during processing. At the same time, when the laser cuts the pipe, the crack of the pipe is also well handled.

Three advantages of tube laser cutting machine:

- Narrow slit, small deformation of workpiece

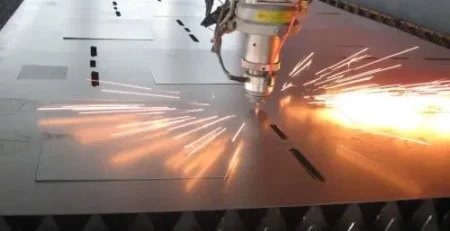

The laser beam of the tube cutter is focused into a very small spot, allowing the focal point to achieve a high power density. At this time, the heat input by the light beam far exceeds the reflected, transmitted or diffused part of the material, and the material is rapidly heated to the extent of vaporization, forming a hole. With the relative linear motion of the beam and the material, the holes continuously form slits of narrow width. The cutting edge is less affected by heat, and the workpiece is basically not deformed.

- Non-contact processing

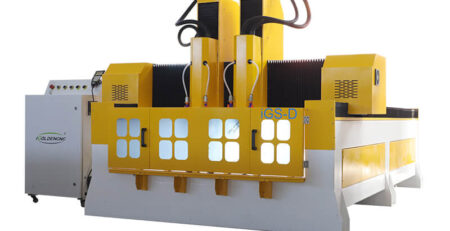

The laser beam of the pipe cutting machine is focused to form a strong point of action, which has many characteristics when applied to cutting. First, the laser energy can be converted into amazing heat energy and kept in a very small area, which can provide narrow straight edge slits; Second, the laser beam does not exert any force on the workpiece, it is a contactless tool, which It means that there is no mechanical deformation of the workpiece; there is no tool wear, not to mention the problem of tool change; the cutting material does not need to consider its hardness, the ability of the pipe laser cutting machine is not affected by the hardness of the cutting material, and any hardness material can be cut. Third, the laser beam of the pipe laser cutting machine has high controllability, high adaptability and flexibility, which is easy to combine with automation equipment, and it is easier to realize the automation of the cutting process.

- Adaptability and flexibility

Compared with other conventional processing methods, the pipe laser cutting machine has greater adaptability. Compared with other thermal cutting methods, as a thermal cutting process, other methods cannot act on a small area like a laser beam, resulting in a large heat-affected zone with a width of , and the workpiece is deformed significantly. Lasers can cut non-metals, but other thermal cutting methods cannot.

Five features of tube laser cutting machine:

- High precision, high speed, narrow cutting seam, small heat affected zone, smooth cutting surface without burrs.

- The laser cutting head will not touch the surface of the material and will not scratch the workpiece.

- The slit is narrow, the heat affected zone is small, the local deformation of the workpiece is minimal, and there is no mechanical deformation.

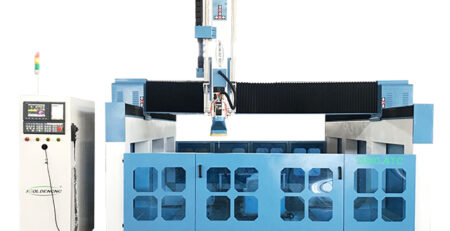

- It has good processing flexibility and can be used to process any shape and cut pipes and other profiles.

- It can cut any hardness materials such as steel, stainless steel, aluminum alloy plate, cemented carbide, etc. without deformation.

All the CNC routers can be shipped worldwide by sea, by air or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with name, email, detailed address, product and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

Leave a Reply

You must be logged in to post a comment.