HOT SALE MACHINE

ABOUT IGOLDENCNC

Shandong iGOLDEN CNC Technology Co., Ltd. established in 2012, is the top CNC machine manufacturer from China, the professional solution supplier of CNC application with key technology and independent intellectual property rights. The company integrates research and development with production, sales and after-sales.

Product lines cover 7 series and more than 100 models, include CNC wood router, CNC foam Cutter, CNC acrylic Cutter, Stone engraving machine, Furniture making machine, Cabinet making machine, Door making machine, CNC milling machine, CNC turning lathe machine, laser cutter, laser engraver, laser marker, CNC plasma cutter, and CNC kits, tools and accessories. We always provide customers with high-quality products, competitive price and excellent service.

WHY CHOOSE IGOLDENCNC

R&D Capabilities

Professional R&D Team

Strict QCS Management

24 Hours Full Service

Grow with Partners

APPLICATION

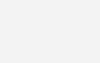

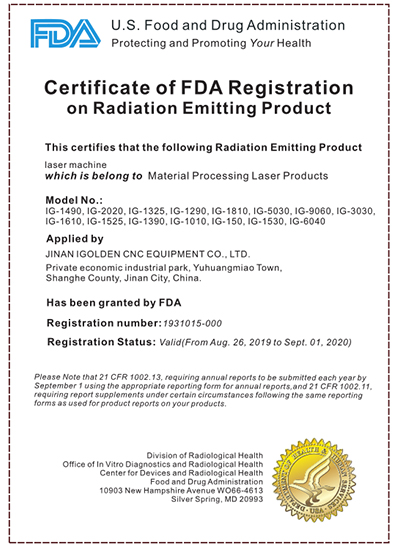

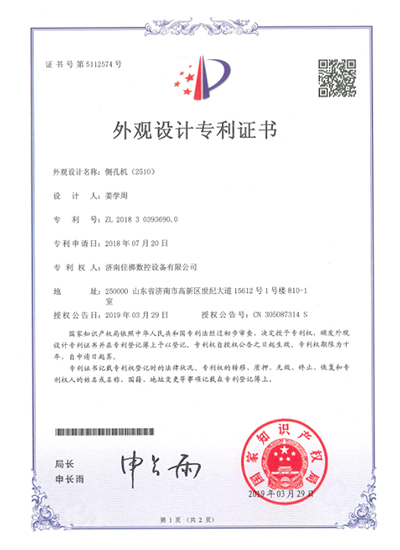

HONOR AND CERTIFICATE

POST & VIDEOS & DOWNLOAD

COOPERATION PARTNER